What is the EDI 947 Warehouse Inventory Adjustment Advice?

The EDI 947 Warehouse Inventory Adjustment Advice communicates inventory changes made at a warehouse or 3PL facility that impact the depositor’s book inventory. The 947 transaction describes increases, decreases, and/or on-hand balances due to cycle count or physical inventory adjustments, concealed or other damages, shrink, expiration or reclassification events; about any type of gain/loss reconciliation that impacts a depositor’s book inventory.

The EDI 947 Inventory Adjustment Advice serves as a system-of-record notification for inventory adjustments that originate from the warehouse. It ensures that the depositor’s ERP, OMS, planning, and financial systems maintain a synchronized inventory, improving planning accuracy, reducing allocation errors, and strengthening financial control.

The EDI 947 Inventory Adjustment Advice transaction is a critical transaction for inventory integrity across multi-node networks with outsourced warehousing models (3PL, 4PL, 5PL). The EDI 947 enhances traceability while supporting regional balancing, cross-dock replenishment, and strategic staging for omni-fulfillment, particularly those programs that exhibit high inventory velocity, attend regulated item traceability, D2C or retail replenishment flows where small stock variances can cascade into disruption across the node.

How does PartnerLinQ use the EDI 947 Warehouse Inventory Adjustment Advice?

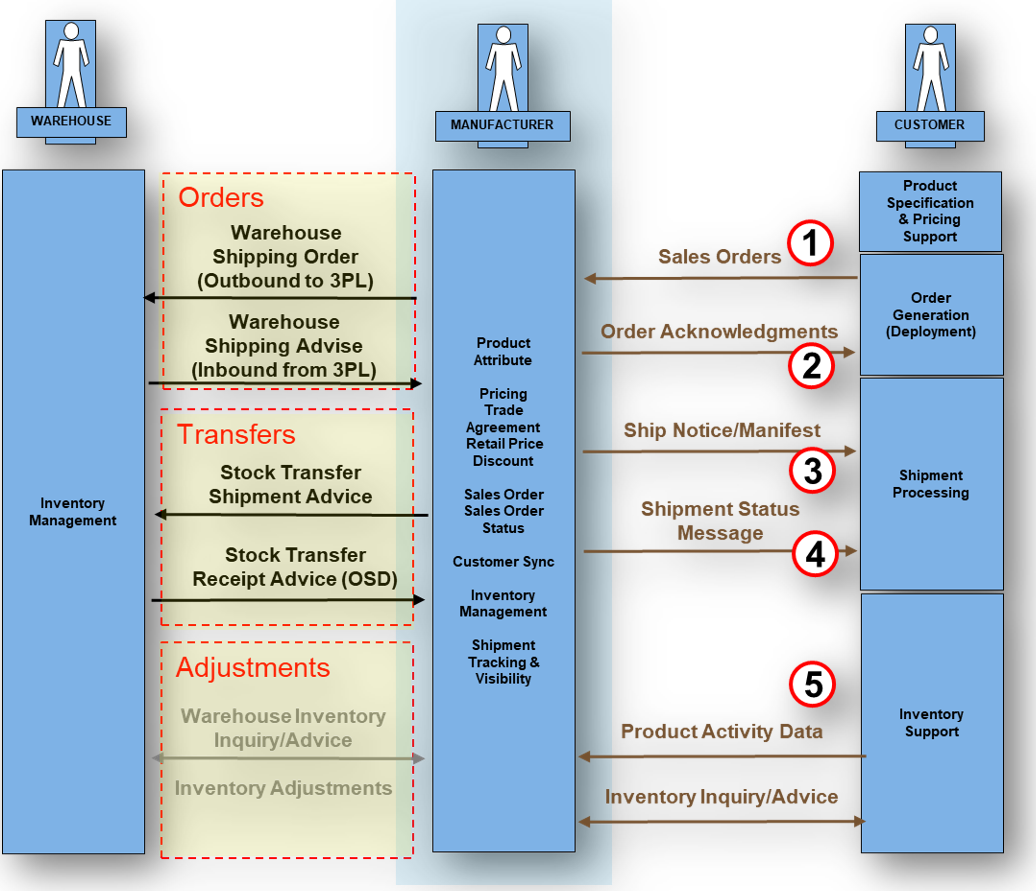

PartnerLinQ uses the Warehouse Inventory Adjustment Advice (947) to communicate changes or adjustments to inventory levels between a warehouse and its trading partners (e.g., suppliers, retailers, or manufacturers) when inventory conditions change. It provides detailed information about modifications to inventory records, as might be the case when the warehouse operator encounters over, short or damaged (OSD) product; a condition which may be the result of warehouse damage, receiving damage, or previously concealed damage of product or products, within a carton and/or within a shipment previously received.

uses the Warehouse Inventory Adjustment Advice (947) to communicate changes or adjustments to inventory levels between a warehouse and its trading partners (e.g., suppliers, retailers, or manufacturers) when inventory conditions change. It provides detailed information about modifications to inventory records, as might be the case when the warehouse operator encounters over, short or damaged (OSD) product; a condition which may be the result of warehouse damage, receiving damage, or previously concealed damage of product or products, within a carton and/or within a shipment previously received.

PartnerLinQ processes outbound EDI 947 messages to send inventory adjustments to Depositor partners:

- Identifying product movement and location updates

- Creating an audit trail for compliance and finance

Reconciles inventory activity with item master references.

Reconciles inventory activity with item master references.- Apply quantity adjustments to book inventory.

- Synchronizes ERP and WMS availability.

- Triggers exception workflows for high-impact adjustments

PartnerLinQ processes inbound EDI 947 messages to capture inventory adjustments made by warehouse partners:

- Creates audit trails for compliance and finance.

- Validating warehouse adjustment activity

- Reconciles identifiers and item master references.

- Applies quantity adjustments to book inventory.

- Synchronizes ERP and WMS availability.

- Triggers exception workflows for high-impact adjustments

PartnerLinQ aligns reported adjustments with internal tolerance thresholds, allowing auto-post for standard corrections and review paths for exceptions, shrink events, and serialized adjustments.

What responses to the EDI 947 Warehouse Inventory Adjustment Advice are expected/sent?

A stand -  alone transaction when most inventory transactions are paired (e.g.; 940/945, 943/944) the EDI 947 Warehouse Inventory Adjustment Advice is a mechanism by which inventory adjustments can be made by the warehouse when a need arises, that being said, there are few practical responses to the EDI 947 Warehouse Inventory Adjustment Advice transaction beyond the following

alone transaction when most inventory transactions are paired (e.g.; 940/945, 943/944) the EDI 947 Warehouse Inventory Adjustment Advice is a mechanism by which inventory adjustments can be made by the warehouse when a need arises, that being said, there are few practical responses to the EDI 947 Warehouse Inventory Adjustment Advice transaction beyond the following

- 997 / 999 Functional Acknowledgment (structure/receipt)

- System acknowledgment / posting event.

- System acknowledgment (internal posting confirmation)

- Occasional ‘Exception’ workflows - triggered by variances.

- Suggested ‘Movement’ workflows - triggered by supply or demand influences.

What are the Key Features of the EDI 947 Warehouse Inventory Adjustment Advice?

The EDI 947 Warehouse Inventory Adjustment Advice reports inventory adjustments at the item, location, or lot level. It advises recipients of changes to stock quantities, ensuring real-time visibility into warehouse stock discrepancies. Common triggers include cycle counts, audits, shrinkage, or overage discoveries.

Feature Description Flexible Adjustment Types Supports various adjustment reasons via codes (e.g., physical inventory, transfers, expirations). Allows for partial or full adjustments, with optional lot/serial tracking for traceability in industries like pharmaceuticals or perishables. Hierarchical Structure It can include loops for multiple locations (e.g., bins, zones) within a warehouse, enabling granular reporting. Optional segments like LIN (Item Detail) and PID (Product Description) add context for non-standard items. Interoperability Compliant with X12 standards (versions like 4010 or 5010). Integrates seamlessly with ERP systems (e.g., SAP, Oracle) and WMS (Warehouse Management Systems) for automated processing. Error Handling and Confirmation Supports functional acknowledgments (EDI 997) for validation. Includes reference numbers for tracing adjustments back to source documents like receipts (EDI 944) or orders.

What does the EDI 947 Warehouse Inventory Adjustment Advice support?

The EDI 947 transaction supports increases, decreases, in inventory, on-hand balances due to cycle count or physical inventory adjustments, concealed or other damages, shrink, expiration or reclassification events; just about any type of gain/loss reconciliation that impacts a depositor’s book inventory, changes like the following…

- Gain/loss reconciliation.

- Adjustments to Inventories resulting from customer return.

- Damage, shrink, aging, expiration or reclassification

- Cycle count variance reporting.

- Serialized/lot correction management/handling.

What is the Purpose of the EDI 947 Warehouse Inventory Adjustment Advice?

The EDI 947 Warehouse Inventory Adjustment Advice reports inventory adjustments made by the warehouse so the value of an inventory (Book Inventory) as reported in the depositor’s (financial, ERP) systems can remain synchronized with the physical inventory, reducing exposure to fulfillment errors and financial misstatement. Physical inventory adjustments reported by the EDI 947 can occur at the item, location, or lot level. The 947 advises recipients of changes to stock quantities, ensuring real-time visibility into warehouse stock discrepancies. Common triggers include cycle counts, audits, shrinkage, or overage discoveries.

What Information is Included in the EDI 947?

The EDI 947 Warehouse Inventory Adjustment Advice includes a lot of detail about the items being adjusted in the W19 segment. The primary purpose of the W19 Warehouse Adjustment Item Detail is to communicate the quantity, product identification, and reason for the adjustment of an item in the warehouse's inventory records.

| Category | Description |

|---|---|

| Item and Location Data | Item number (GTIN, UPC, SKU) – (W1906); Warehouse, bin, location (DUNS, GLN) |

| Adjustment type | Gain, loss, shrink, damage, expiration, reclassification |

| Quantity & UOM | Adjusted units in primary or alternate UOM |

| Batch/Lot, Serialization | Track-&-Trace details when applicable |

| Reason Code | Qualifier indicating why the adjustment occurred (W1901) |

| Totals | Summary quantity adjustments and impact |

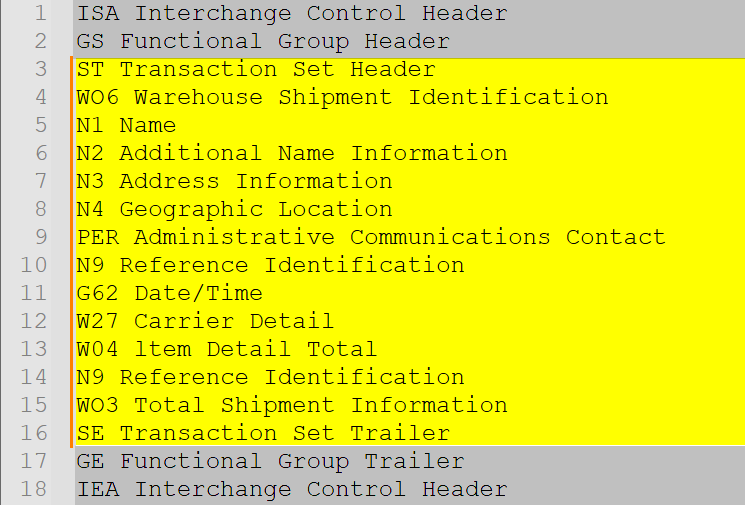

What are the Essential Components of the EDI 947 Warehouse Inventory Adjustment Advice?

| Segment | Purpose |

|---|---|

| ST Transaction Set Header | Transaction Control indicates the start of a transaction |

| W15 Warehouse Adjustment Identification | Adjustment Header - header-level identification and summary information for the inventory adjustment transaction. |

| N1 - N4 | Party/warehouse IDs - to identify locations as they pertain to the transaction at hand |

| N9 Extended Reference Information | Reference identifiers - data carriers with which to identify information specific to the transaction |

| W19 Warehouse Adjustment Item Detail | Adjustment line detail - detailed information about item-specific inventory adjustments including product IDs and quantities when inventory conditions change |

| SE | Transaction Control indicates the end of a transaction |

What are the Common Segments Included in the EDI 947 Warehouse Inventory Adjustment Advice?

| Segment / Element | Meaning |

|---|---|

| ST01/ST02 | Transaction Control indicates the start of a transaction |

| W1501 | Adjustment type - Gain, loss, correction, damage |

| N103/N104 | Location qualifier and code (Depositor, Warehouse) |

| N901/N902 | Reference identifiers - data carriers with which to identify information specific to the transaction |

| G62 | Date/Time |

| W1902/W1903 | Qty & UOM – primary, secondary, and traceability element identification |

What Status Codes are used with the EDI 947 Warehouse Inventory Adjustment Advice?

While a Transaction Set Purpose Code (W1501) is available within the EDI 947 Warehouse Inventory Adjustment Advice it has given way to unique transaction identification (Adjustment Number W1502). The use of a unique transaction identification essentially means that every transaction is an adjustment and if for example Transaction1 indicates ‘shrink’, when the ‘lost’ inventory is later found, it is reported in Transaction 2, each transaction accompanied with a reason code, found in the W19 Warehouse Adjustment Item Detail; Transaction 1 indicating ‘04’ Receipt Less Than Previously Reported in the W1901 and Transaction 2 later indicating the same item as ‘AA’ Physical Count in the W1901.

What Reason Codes are used with the EDI 947 Warehouse Inventory Adjustment Advice?

Typical examples include:

| Qualifier | Description |

|---|---|

| 03 | Shipment Greater Than Previously Reported |

| 04 | Receipt Less Than Previously Reported |

| 53 | Shipment Less Than Previously Reported |

| 54 | Receipt Greater Than Previously Reported |

| 55 | Product Taken Off Hold |

| AA | Physical Count |

| AU | Damaged in Facility |

| AV | Damaged in Transit |

| DL | Damage Loading |

| HD | Hidden Damage (Suspected or Actual) |

| NR | Not Reported |

What Use Cases does the EDI 947 Warehouse Inventory Adjustment Advice support?

The EDI 947 Warehouse Inventory Adjustment Advice is used in supply chain management to report changes in warehouse inventory levels.

| Use Case | Specific Scenarios | Benefits |

|---|---|---|

| Inventory Verification | Physical inventory and cycle count for high-value or fast-moving items. | Identifies overages/shortages quickly; reduces audit times and automates book inventory reconciliation. |

| Loss and Damage Management | Adjustments for damaged, expired, obsolete goods, or shrinkage due to theft, loss, or other factors. | Enables precise loss tracking; supports insurance claims and FIFO/LIFO compliance. |

| Returns and Reversals | Customer and vendor returns inventory processing (defective, damaged, expired, obsolete). | Speeds item restocking and movement support of returns to ‘saleable’ inventories while minimizing holding costs for returned goods. |

| Operational Corrections | Provides a mechanism to correct data entry errors in receipts (EDI 944) or shipments (EDI 945) and make post transactional adjustments. | Maintains data integrity and synchronized inventories reducing warehouse stock discrepancies and preventing cascading errors. |

| Transfers and Movements | Inter-warehouse or inter-location stock transfers, shifts, reallocations, or temporary loans. | Provides real-time visibility for multi-site operations; item stocking and restocking, support of returns, load balancing. |

| Regulatory and Traceability | Lot/serial number adjustments for recalls or compliance. Expiration-based removals in regulated industries (e.g., pharma, food). | Enhances traceability; complies with standards like GS1 or FDA requirements (FSMA/DSCSA). |

What are the Benefits of the EDI 947 Warehouse Inventory Adjustment Advice?

| Benefit | Outcome |

|---|---|

| Inventory synchronization and Warehouse Visibility | Prevents false availability and provides immediate notifications of inventory changes (e.g., due to counts, damage, or returns), ensuring all parties have up-to-date stock data to prevent stockouts or overstocking. |

| Operational Transparency (3PL) | Offers detailed breakdowns of adjustments (e.g., quantities, reasons, locations), eliminating surprises and building trust in multi-party supply chains. |

| Inventory Accuracy, Order Management, and Fulfilment Rate Improvements | Automates adjustment reporting, reducing customer impact by reducing manual data entry errors and discrepancies between warehouse records and trading partners' systems. |

| Cost Savings | Minimizes delays, holding costs, and lost sales from inventory mismatches and returns, supports better forecasting and resource allocation. |

| Regulatory Compliance | Facilitates traceability for lot/serial adjustments, aiding audits in regulated sectors like pharma or food, and ensures accurate reporting for financials. |

| Enhanced Efficiency | Speeds up reconciliation processes, cutting down on time spent on audits or corrections, and integrates seamlessly with WMS/ERP for faster operations. |

| Scalability for High-Volume Ops | Handles batch adjustments efficiently, ideal for large-scale warehouses or global networks, reducing paperwork and supporting just-in-time inventory. |

How efficient is the EDI 947 Warehouse Inventory Adjustment Advice?

The EDI 947 Warehouse Inventory Adjustment Advice reduces manual reconciliation through automation. It accelerates book inventory balancing, helps ensure ATP (Available-to-Promise) planning, fill rates, and financial accuracy (posting).

EDI 947 Warehouse Inventory Adjustment Advice reduces manual reconciliation through automation. It accelerates book inventory balancing, helps ensure ATP (Available-to-Promise) planning, fill rates, and financial accuracy (posting).

How compliant is the EDI 947 Warehouse Inventory Adjustment Advice?

The EDI 947 Warehouse Inventory Adjustment Advice aligns with X12 v4010 standards, GS1 SSCC, EPC guidance, and common AS2 transport practices and protocols, The 947 supports global warehouse networks and industry audit controls and is used in PartnerLinQ-connected ecosystems.

- X12 v4010 structure

- Support for GS1 SSCC labeling

- EPC/RFID compliance when applicable

- Standard EDI control structure and acknowledgments

What is the Format of the EDI 947 Warehouse Inventory Adjustment Advice?

The EDI 947 uses the ANSI X12 Warehouse Inventory Adjustment Advice for digital stock alignment with physical inventories, shipment adjustments, and warehouse receipt adjustments.

How Accurate is the EDI 947 Warehouse Inventory Adjustment Advice?

Accuracy depends on synchronized master data, identifiers, location codes, and partner code lists; validation of ST/SE control numbers and mandatory content supports processing integrity.

- Synchronized item and location master data.

- Valid SSCC/lot/serial identifiers

- SSCC and serial validation when used.

- Time-aligned ERP and WMS posting cycles.

- Strong discrepancy handling processes

What are the Limitations of the EDI 947 Warehouse Inventory Adjustment Advice?

Limitations of the EDI 947 Warehouse Inventory Adjustment include discipline and automation. The EDI 947 provides exception-only reporting which requires strong controls (discipline) and or automation of serialized adjustments (W1502 Adjustment Number) and master data maturity.

of the EDI 947 Warehouse Inventory Adjustment include discipline and automation. The EDI 947 provides exception-only reporting which requires strong controls (discipline) and or automation of serialized adjustments (W1502 Adjustment Number) and master data maturity.

The operational maturity of a warehouse operation is also a limitation on the EDI 947 Warehouse Inventory Adjustment Advice as manual warehouse processing can reduce the accuracy of digital stock alignment possibilities of the EDI 947 Warehouse Inventory Adjustment Advice.

Are Guidelines & Sample Files for the EDI 947 Warehouse Inventory Adjustment Advice available?

Yes. PartnerLinQ provides sample EDI 947 Warehouse Inventory Adjustment Advice Transaction and implementation guides through its Support and Guideline Management Team.

Sample EDI 947 implementation guides illustrate both inbound and outbound flows, segment layouts, and valid data examples and support testing and partner onboarding. Customized specification documents for use in on boarding and technical development are available upon request.

PartnerLinQ provides:

- EDI 947 Warehouse Inventory Adjustment Advice transaction implementation guide

- Sample payloads

- Qualification and testing maps

- Error handling and best-practice notes

What are the Basic Questions for EDI Integration with the EDI 947 Warehouse Inventory Adjustment Advice?

- Are there Samples and Specs available?

- What is the general direction of the transaction?

- Are they Inbound to the client or Outbound to another party?

- Are more than one trading partner exchanging the 947 Warehouse Inventory Adjustment Advice?

- Are there other interested parties?

- What other transactions might these interested parties be a party to?

- Will adjustments be sent in full detail or with exceptions-only?

- What response is expected or sent in response to the transaction?

- Is a response to the transaction a timed event? Are notifications involved/needed?

- What happens after the transaction is sent/received?

- What is the posting latency tolerance?

- What approvals are needed before auto-posting?

- What variance thresholds trigger review?

- How is adjustment reason coded and tracked?

- Are responses and changes automatically triggered? (an internal systems trigger) Or do transactions require human intervention?

- Do Batch or Lot numbers need to be tracked? Is there serialization?

- Will SSCC and EPC/RFID be captured?

- Which date qualifiers are mandatory?

- Are serialized and lot-controlled items included/ required?

- Are products consolidated and presented as single line items, or are sublines involved?

- How are changes to the 947 Warehouse Inventory Adjustment Advice business message managed today?

- Is there automation? (an internal systems trigger) Or are 947 Warehouse Inventory Adjustment Advice business message transactions triggered manually?

What Business Level Workflow does the EDI 947 Warehouse Inventory Adjustment Advice support?

Warehouse posts to local WMS →

EDI 947 sent to depositor →

Platform validates + applies →

ERP / OMS / ATP updated →

Audit + exception controls kick in if needed.

- Initiation: The Warehouse identifies an adjustment need and sends an EDI 947 Warehouse Stock Transfer to the depositor, identifying items, quantities, and shipping details.

- Processing: The Warehouse posts changes to local WMS

- Acknowledgment: The depositor sends an EDI 997 Functional Acknowledgment back to the warehouse to confirm receipt and process the contents of the EDI 947, updating inventories.

- Validation: The depositor validates the EDI 944 against the original EDI 943 for accuracy, often via automated ERP integration.

- Reconciliation and Updates: The depositor receives the EDI 947, reconciles discrepancies (e.g., exceptions, Over, Short, & Damaged (OSD)), updates inventory records and adjusts inventory and locations accordingly.

- Downstream Activities: Data contained by the EDI 947 Warehouse Inventory Adjustment Advice may trigger additional steps, steps such as generating an EDI 943 to notify the warehouse of a required movement of inventory.

What are the Best Practices for using the EDI 947 Warehouse Inventory Adjustment?

The Best Practice for using the EDI 947 Warehouse Inventory Adjustment is keeping the process as simple as possible, for example, the use of positive numbers (intergers) – there is no such thing as a negative inventory given its physicality and while a ‘Book Inventory’ may go below zero, a physical inventory cannot. There can be an expectation of inventory. An expectation of an inventory is considered ‘In transit’ and ‘In transit’ inventory is again always a positive number. Therefore if inventory = ‘0’, use alerting to notify interested parties if/when ‘In transit’ inventory is also = ‘0’, a condition that would most certainly result in an out of stock condition and fulfilment failure, and if both inventories = ‘0’, consider removing the item from the catalog seasonally or permanently.

Best Practice

The manufacturer manages the inventory and the logistics provider (3PL) reports the inventory on hand, (i.e. the 3PL send ‘AA’ Physical Count in the W1901 where W1902 is always 0 (zero) or a positive number to indicate the actual inventory is reported and as a result, PartnerLinQ makes the inventory adjustment in the ERP (i.e. G/L, Book).

| Best Practice | Description |

|---|---|

| Standardize Data Mapping and Codes | Use consistent qualifiers to prevent mapping errors. Conduct joint mapping sessions and document in a shared guideline (e.g., via EDI Implementation Guide) and share across all trading partners. Example: reason codes (e.g., 'AU' for Damaged in Facility, 'HD' for Hidden Damage, ‘AB’ for accounting error). |

| Implement Robust Validation and Acknowledgments | Require EDI 997 Functional Acknowledgments to ensure delivery success, catch issues early and avoid inventory discrepancies. Validate incoming files for completeness. Use syntax and semantic checks and automate alerts to avoid inventory discrepancies. |

| Integrate Seamlessly with WMS/ERP Systems | Automate the EDI 947 transmission from the Warehouse Management System (WMS); automation reduces manual intervention. Trigger adjustments based on events like cycle counts or returns in support of real-time updates. Enable bi-directional automation flows with related sets (e.g., 846/847 for inventory inquiries and advice). |

| Perform Regular Testing and Audits | Conduct end-to-end testing regularly to identify irregularities and bottlenecks. Include positive/negative scenarios and audit transaction volumes and monthly error rates through regular cycle counting. |

| Prioritize Security and Compliance | Encrypt transmissions via AS2 or SFTP to protect sensitive inventory data. Include traceability elements like lot numbers for regulated industries and log adjustments for audit trails. |

| Monitor and Optimize Performance | Drives continuous improvement by tracking KPIs like processing times (<24 hours) and error rates (<1%). Use analytical tools to refine/reduce reason codes based on commonality. Implement dashboard tools to improve overall visibility. |

What Transactions are associated with the EDI 947 Warehouse Inventory Adjustment?

| Transaction | Role |

|---|---|

| 940 | Warehouse Shipping Order |

| 943 | Warehouse Stock Transfer Shipment Advice |

| 944 | Warehouse Stock Transfer Receipt Advice |

| 945 | Warehouse Shipping Confirmation |

| 997 | Functional Acknowledgment |

| 999 | Implementation Acknowledgment |

Footnotes

- PartnerLinQ 947 Warehouse Adjustment Notes

- X12 v4010 947 Segment Reference Guide

- GS1 Serialized + Lot Traceability Guidance

Explore Our Integration Solutions

PartnerLinQ Integration Solutions

Connect Everything. Integrate Intelligently.

Future-Proof Your Business with Composable, AI Powered Connectivity.