What is the EDI 943 Warehouse Stock Transfer Shipment Advice?

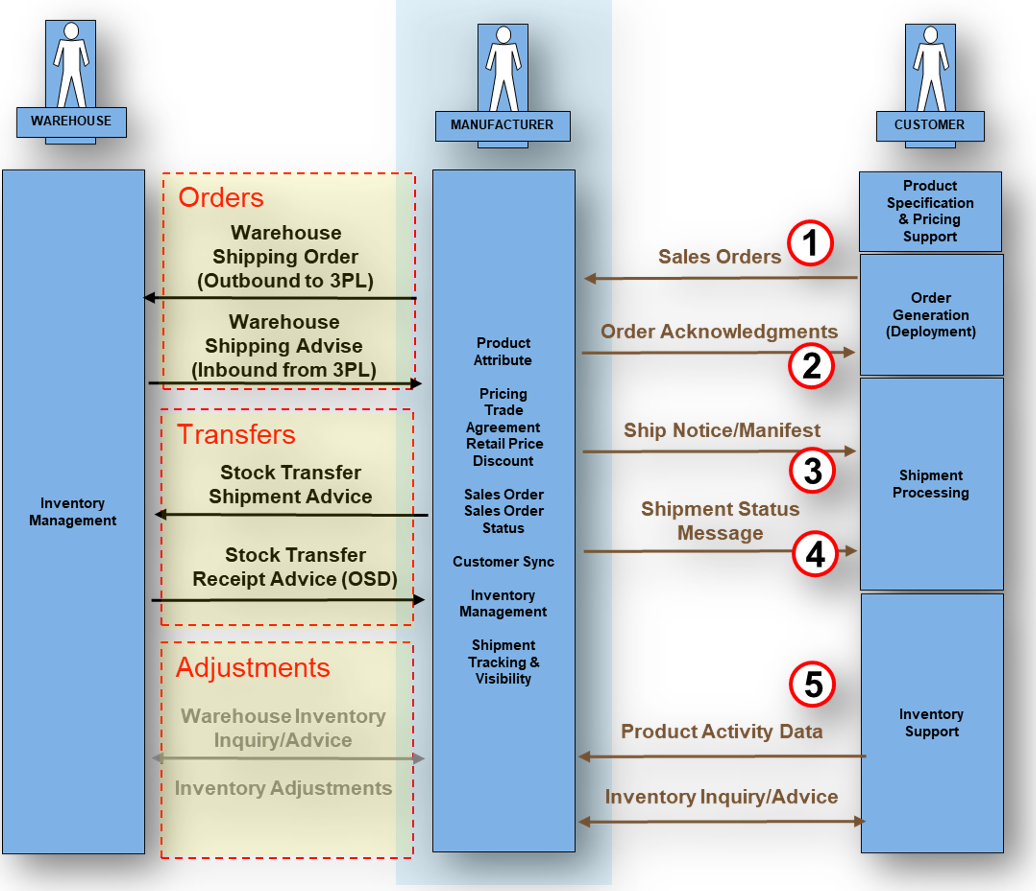

The EDI 943 Warehouse Stock Transfer Shipment Advice notifies a public warehouse or third-party logistics provider (3PL) that a stock transfer shipment has been made and is in transit to the warehouse. It replaces or eliminates faxes, emails, telephone calls, and paper instructions with a standards-based electronic (digital) message that provides shipment identifiers, inventory detail, references, carton and pallet information, and arrival expectations, information strikingly similar in structure to an ASN.

The EDI 943 transaction prepares the receiving warehouse to receive the inbound shipment, allocate dock space, resources, labor, in short, plan the inbound logistics flow before the trailer arrives. The EDI 943 message supports each, pack, case and pallet-level identification of items, GS1 Serial Shipping Container Code (SSCC) labeling, GTIN, UPC, EPC, and RFID data carriers, batch/lot-based and serialized traceability elements that may be required in certain high value or regulated supply chains including food products, consumer goods, pharmaceuticals, and certain high value electronic and retail products.

The EDI 943 Warehouse Stock Transfer Shipment Advice aligns system expectations between nodes, reduces receiving errors, accelerates unloading, improves slotting accuracy, and strengthens end-to-end supply chain traceability. It is the internal transfer counterpart to the 940 Warehouse Shipping Order, and the lifecycle completes when the warehouse returns a 944 Warehouse Stock Transfer Receipt Advice.

How does PartnerLinQ use the EDI 943 Warehouse Stock Transfer Shipment Advice?

PartnerLinQ uses the EDI 943 Warehouse Stock Transfer Shipment Advice (943) to advise a public warehouse that a transfer shipment has been made or is pending, providing the public warehouse with detailed information concerning the product(s) being shipped to that location. The platform leverages pre-configured trading partner maps to ensure alignment with each warehouse’s requirements and to validate details such as product identifiers, SSCCs, quantity fields, dates, and references.

PartnerLinQ  tracks and monitors EDI 943 transmissions, acknowledgments, and responses and ties the EDI 943 to its corresponding EDI 944 receipt and inventory update. The platform supports SSCC label standards, EPC/RFID serialization, and lot/expiration handling for regulated categories. Advanced lifecycle monitoring and alerts advise users of exceptions including OSD (Over, Short, & Damaged).

tracks and monitors EDI 943 transmissions, acknowledgments, and responses and ties the EDI 943 to its corresponding EDI 944 receipt and inventory update. The platform supports SSCC label standards, EPC/RFID serialization, and lot/expiration handling for regulated categories. Advanced lifecycle monitoring and alerts advise users of exceptions including OSD (Over, Short, & Damaged).

The EDI 943 Warehouse Stock Transfer Shipment Advice (943) transaction enables receiving teams to pre-receive inventory, verify shipments on arrival, accelerate dock processing, and ensure accurate financial and operational posting.

What responses to the EDI 943 Warehouse Stock Transfer Shipment Advice are expected or sent?

Warehouses respond with the EDI 944 Warehouse Stock Transfer Receipt Advice

to confirm shipment receipt and variances. The EDI 997 and EDI 999, also part of response processing provide syntax acknowledgments when required. The Functional Acknowledgment (997) is an ANSI X12 EDI transaction set that represents industry’s best practice and is automatically generated by modern EDI software. The Implementation Acknowledgment (999) is an ANSI X12 transaction set designed to provide detailed feedback on the acceptance or rejection of received EDI transactions. Unlike the 997, which only indicates syntactical validity, the Implementation Acknowledgment (999) also evaluates compliance against published implementation guides.

What does the EDI 943 support?

The EDI 943 Warehouse Stock Transfer Shipment Advice supports multi-warehouse and 3PL execution, the use of the GS1 barcode and Electronic Product Code / Radio Frequency Identification (EPC/RFID) data carriers and product serial number identification, and shipment details and while not recommended for use with Stock Transfers, the NTE (Note/Special Instruction) segment is also supported.

- Advance inbound warehouse notifications

- Internal stock transfer execution between distribution nodes

- Serialized and lot-controlled tracking.

- GS1 SSCC / EPC / RFID identification

- Carrier and bill-of-lading reference passing

- Dock and labor scheduling

- Cross-dock and forward-staging workflows

- High-velocity retail and CPG inbound models

What are the Key Features of the EDI 943 Warehouse Stock Transfer Shipment Advice?

| Feature | Description |

|---|---|

| Advance stock notification | Provides the receiving warehouse visibility into shipments and expected inventory additions, allowing the warehouse time to plan for ‘put-away’ processes. |

| Advance carrier information | Communicates BOL, PRO, tracking, and ship references. |

| Labor and dock planning | Enables staging and resource allocation by preparing the receiving warehouse to receive the inbound shipment, allocate dock space, resources, and labor, and plan the inbound logistics flow before the trailer arrives. |

| ‘Value Add’ process planning | Enables omni-channel allocation and staging, allowing the warehouse time to plan for advanced 3P functions including value-add and ‘put-together’ processing. |

| Exception management | Prepares warehouse for discrepancy reporting. |

| Regulated handling support | Captures lot, expiration, and temperature controls. |

| Serialized control | Supports SSCC and EPC tracking for pallets and cases. |

What is the Purpose of the EDI 943 Warehouse Stock Transfer Shipment Advice?

The EDI 943 prepares a warehouse to receive an inbound transfer shipment with visibility into items, quantities, packaging, and references, supporting accurate and efficient receiving operations.

Typical Information Included:

| Category | Description |

|---|---|

| Warehouse locations | Depositor, ship-from, ship-to identifiers. |

| Shipment identifiers | Transfer number, shipment ID, BOL, carrier references. |

| Schedule | Expected arrival date and time. |

| Special handling | Temperature, hazard, and priority flags. |

| Pallet/carton detail | SSCC, EPC/RFID when used. |

| Product detail | Item number, quantity, UOM, packaging. |

| Lot and serial data | Lot, batch, expiration, and serial where required. |

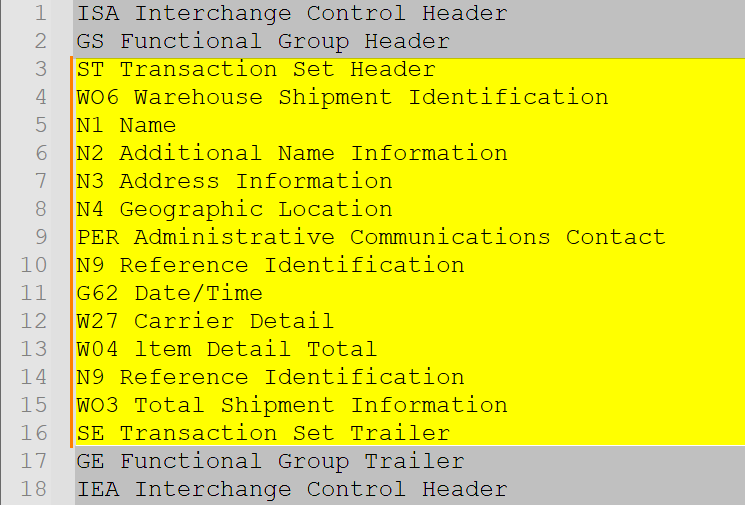

What are the Essential Components & Segments of the EDI 943 Warehouse Stock Transfer Shipment Advice?

| Segment | Purpose |

|---|---|

| W06 | Inventory transfer shipment identification. |

| N1 – N4 | Name and address segments for ship-from and receiving warehouse. |

| N9 | Reference identification (SID, BOL, PRO, PO, carrier tracking). |

| G62 | Date and time qualifiers. |

| W01 | Line-item detail. |

| G69 | Item descriptions. |

| W76 | Roll-up totals (quantities, weight, volume). |

What Common segments/element are Included in the EDI 943 Warehouse Stock Transfer Shipment Advice?

| Segment / Element | Role |

|---|---|

| W0601 | Indicates original, full, replacement, or exceptions-only mode. |

| N103 / N104 | Party identifier qualifiers and codes. |

| N9 | Reference identification (SID, BOL, PRO, PO, carrier tracking). |

| G6201 | Date qualifiers (ship date, expected arrival, issue date). |

| W76 | Roll-up totals (quantities, weight, volume). |

What Status Codes are used with the EDI 943 Warehouse Stock Transfer Shipment Advice ?

Typical status and action indicators used with the EDI 943 can be found in the found in the W0601 Reporting Code. This code identifies the purpose of the transaction set, such as creating an Original Transaction or Full Detail, indicating the transaction contains 'Full Detail' an approach allowing the sender to include all information and the receiver the ability to overwrite shipment data, information each time, Replacement and Charge, and cancellations.

- Original Transaction

- Full Detail – e.g., Full refresh a ‘change by refresh’ process for partners who expect Warehouse Shipping Order to change and anticipate the use of change or replacement orders.

- Exceptions - change is only communicated where the change has occurred.

- Cancellation

- Replacement and Charge (where supported)

What Reason Codes are used with the EDI 943 Warehouse Stock Transfer Shipment Advice ?

While the EDI 943 Warehouse Stock Transfer Shipment Advice is a one-way, advance notification sent from a supplier or manufacturer to a warehouse to inform them of an incoming stock transfer, there are Action Codes (Element 306 in W06 Segment), codes that can indicate an action taken or the status of the warehouse shipment advice in flight.

- *Change or Correction - Shipment correction, Item substitution

- Lot or unit removal

- Equipment additions

- Packaging or pallet pattern change

- Routing or carrier change

*Note: PartnerLinQ suggests utilizing a ‘Change-by-Refresh’ process for partners who expect Warehouse Shipping Order to change and anticipate the use of change or replacement orders.

What Use Cases does the EDI 943 Warehouse Stock Transfer Shipment Advice support?

| Use Case | Supported Business Processes |

|---|---|

| Inbound Stock Transfer Notification | Inventory forecasting and replenishment; dock scheduling and labor planning; automated receiving preparation. |

| Customer Return Authorization | Return goods handling; reverse logistics coordination; inventory adjustment upon receipt. |

| Carrier and Shipment Tracking Coordination | Logistics preparation; carrier synchronization; transit visibility for goods in motion. |

| Inter-Warehouse Stock Movement | Stock redistribution; location updates; real-time inventory synchronization across facilities. |

| Inventory Record Updates | Automated data entry for stock accuracy; reconciliation of shipped vs. received quantities; reduction in manual errors. |

| Regional Replenishment for Retail, Convenience, and Grocery Networks | Demand-driven replenishment; route optimization for perishable goods; multi-site inventory leveling. |

| 3PL Fulfillment for Direct-to-Store and Direct-to-Consumer Models | Order fulfillment orchestration; last-mile preparation; integration with e-commerce platforms. |

| Cold-Chain and Regulated Supply Chain Execution with Special Handling | Temperature logging; compliance certification; chain-of-custody documentation. |

| Export Logistics with Sealed Pallets and Serial Control | Export compliance; serial number validation; pallet-level tracking for global handoffs. |

| Vendor-Managed Inventory in Public Warehousing | VMI replenishment cycles; space allocation in multi-tenant facilities; automated threshold alerts. |

| Cross-Dock and Flow-Through Environments | Cross-dock sorting; flow-through labeling; minimal dwell-time processing. |

| Omni-Channel Allocation and Staging | Channel-specific inventory splitting; staging for blended orders; real-time availability syncing. |

| DC to DC Transfers | Inter-DC routing; consolidation of partial loads; capacity planning across networks. |

What are the Benefits of the EDI 943 Warehouse Stock Transfer Shipment Advice?

| Benefit | Result |

|---|---|

| Operational readiness | Faster unloading and slotting. |

| Improved inventory accuracy | Stronger alignment with ERP expectations. |

| Serialized traceability | Enhanced chain-of-custody confidence. |

| Reduced delays | Fewer blind receipts and receiving bottlenecks. |

| Lower labor cost | Better inbound workforce planning. |

| Higher On-Time, In-Full (OTIF) | Greater On-Time, In-Full execution reliability. |

How efficient is the EDI 943 Warehouse Stock Transfer Shipment Advice?

Automation is very efficient when compared to manual execution, and the EDI 943 Warehouse Stock Transfer Shipment Advice is no exception. The 943 reduces receiving time, eliminates blind unloads, supports automated matching, and accelerates posting to on-hand. The result, information exchanged between parties is increasingly accurate, particularly when automatically reconciled by way of the EDI 944 and 947 with alerting and/or exception reporting.

How compliant is the EDI 943 Warehouse Stock Transfer Shipment Advice?

The  EDI 943 Warehouse Stock Transfer Shipment Advice aligns with X12 v4010 standards, GS1 SSCC, EPC guidance, and common AS2 transport practices and protocols, The 943supports global warehouse networks and industry audit controls and is used in PartnerLinQ-connected ecosystems.

EDI 943 Warehouse Stock Transfer Shipment Advice aligns with X12 v4010 standards, GS1 SSCC, EPC guidance, and common AS2 transport practices and protocols, The 943supports global warehouse networks and industry audit controls and is used in PartnerLinQ-connected ecosystems.

- X12 v4010 structure

- Support for GS1 SSCC labeling

- EPC/RFID compliance when applicable

- Standard EDI control structure and acknowledgments

What is the Format of the EDI 943 Warehouse Stock Transfer Shipment Advice?

The EDI 943 uses the ANSI X12 Warehouse Stock Transfer Shipment Advice for digital stock transfer shipments and shipments in transit to a warehouse, warehouse receipt, and shipment notification.

How Accurate is the EDI 943 Warehouse Stock Transfer Shipment Advice?

Accuracy depends on synchronized identifiers, location codes, and partner code lists; PartnerLinQ validations on ST/SE control numbers and mandatory content support processing integrity.

What are the Limitations of the EDI 943 Warehouse Stock Transfer Shipment Advice?

Adoption, Adoption depends on partner maturity regarding their business processes and WMS, and agreement on refresh versus cancel/replace strategy for change management. Advanced capabilities such as handling Batch/lot or advanced serialized might limit adoption in certain high value or regulated supply chains.

- Warehouse must support EDI receipts or pre-receipts.

- Exceptions-only mode requires strong error handling discipline.

- SSCC/EPC requires more advanced capabilities.

Are Guidelines & Sample Files for the EDI 943 Warehouse Stock Transfer Shipment Advice available?

Yes. Sample EDI 943 Warehouse Stock Transfer Shipment Advice transactions and implementation guides that support testing and partner onboarding are available through PartnerLinQ.

Sample EDI 943 implementation guides illustrate both inbound and outbound flows, segment layouts, and valid data examples and support testing and partner onboarding. Customized specification documents for use in on boarding and technical development are available upon request.

PartnerLinQ provides:

- EDI 943 Warehouse Stock Transfer Shipment Advice implementation guide

- Sample payloads

- Qualification and testing maps

- Error handling and best-practice notes

What are the Basic Questions for EDI Integration with the EDI 943 Warehouse Stock Transfer Shipment Advice?

- Are there Samples and Specs available?

- What EDI version and standard will be used?

- What is the general direction of the transaction?

- Are they Inbound or outbound to another party?

- Is this a full-detail or exceptions-only model?

- What response is expected or sent to the transaction?

- Is a warehouse pre-receive required?

- Are there samples and specs of the response transaction available?

- Are responses and changes automatically triggered? (an internal systems trigger)

- Do transactions require human intervention?

- Are there other interested parties?

- What transactions might these interested parties be a party to?

- Are there order or shipment types that need to be tracked or handled differently?

- Are there any business rules that should be considered when processing Warehouse Stock Transfer Shipment Advice (943)? (e.g., invalid/missing item or customer identification number)

- Do Batch or Lot numbers need to be tracked? Is there serialization?

- Are SSCC and EPC required?

- Which date qualifiers are mandatory?

- Are products consolidated and presented as single line items, or are sublines involved?

- How are changes to the Warehouse Stock Transfer Shipment Advice (943) business message transaction today?

- Is there automation? (an internal systems trigger) Or are Warehouse Stock Transfer Shipment Advice (943) business message transactions triggered manually?

- What is the master data source for item and location codes?

- How are discrepancies resolved?

What Business Level Workflows does the EDI 943 Warehouse Stock Transfer Shipment Advice support?

- Initiation:

The Transfer is initiated, and the depositor sends an EDI 943 Warehouse Stock Transfer to the warehouse, identifying items, quantities, and shipping details.

The Transfer is initiated, and the depositor sends an EDI 943 Warehouse Stock Transfer to the warehouse, identifying items, quantities, and shipping details. - Processing: The warehouse receives the EDI 943 and plans the inbound logistics flow before the trailer arrives.

- Shipment: Once the shipment arrives at the warehouse, the warehouse team receives the shipment, begins ‘put-a-way’ processing, generates and transmits the EDI 944 to the depositor, detailing the items and quantities received, variances, and packaging details within the specified period

- Receipt The depositor receives the EDI 944

- Acknowledgment: The depositor sends an EDI 997 Functional Acknowledgment back to the warehouse to confirm receipt and process the contents of the EDI 944, updating inventories.

- Validation: The depositor validates the EDI 944 against the original EDI 943 for accuracy, often via automated ERP integration.

- Reconciliation and Updates: The depositor reconciles discrepancies (e.g., exceptions, Over, Short, & Damaged (OSD)), updates inventory records and adjusts inventory and locations accordingly.

- Downstream Activities: The EDI 943/944 data may trigger additional steps, steps such as generating an EDI 947 to notify the depositor of discrepancies like concealed damages or shortages uncovered during ‘put-a-way.’

What are the Best Practices for using the EDI 943 Warehouse Stock Transfer Shipment Advice?

| Practice | Benefit |

|---|---|

| Send 943 before freight departs | Like the ASN, EDI 943 Warehouse Stock Transfer Shipment Advice should be automated to ensure it is sent when the dock door closes (“Close Load” in TMS). This allows the receiving warehouse time for dock planning. |

| Utilize a ‘Change-by-Refresh’ process | PartnerLinQ suggests a change-by-refresh process for partners who expect Warehouse Shipping Orders to change. This approach ensures data consistency and reduces state drift when using change or replacement orders. |

| Validate SSCC and Item Master Data | Ensuring scan accuracy is vital to electronic processing. Automation begins with the timely exchange of key data elements, including item catalog data. SSCCs should be validated against the EDI 943 to identify missing pallet items. |

| Include BOL and tracking | Strengthens traceability and appointment setting. |

| Monitor acknowledgments and exceptions | Improves security, trust, and reliability between depositors and warehouses. |

What Transactions are associated with the EDI 943 Warehouse Stock Transfer Shipment Advice?

940/945 (shipment request/confirmation), 850 (PO), 856 (ASN), 944 (stock transfer), 947 (inventory adjustment), 810 (invoice), 997/999 (acks).

| Transaction | Role |

|---|---|

| 850 | Purchase Order |

| 856 | Advance Ship Notice |

| 940 | Warehouse Shipping Order |

| 944 | Warehouse Stock Transfer Receipt Advice |

| 945 | Warehouse Shipping Confirmation |

| 947 | Warehouse Inventory Adjustment Advice |

| 997 | Functional Acknowledgment |

| 999 | Implementation Acknowledgment |

Explore Our Integration Solutions

PartnerLinQ Integration Solutions

Connect Everything. Integrate Intelligently.

Future-Proof Your Business with Composable, AI Powered Connectivity.