What is the EDI 945 Warehouse Shipping Advice?

The EDI 945 Warehouse Shipping Advice confirms that a warehouse executed a shipment request and released goods to a carrier on behalf of the depositor or seller.

This transaction reconciles ordered versus shipped quantities, acknowledges substitutions or shortages, and provides shipment detail that supports invoicing and inventory accuracy. The EDI 945 functions as the authoritative record of warehouse fulfillment, ensuring alignment between warehouse execution and order management systems.

The EDI 945 Warehouse Shipping Advice confirms that a warehouse fulfilled a shipment request and released goods to the transportation provider. This transaction informs the depositor or seller that the order shipped, reconciles order-to-shipment quantities, and provides shipment detail supporting invoicing, transportation, and inventory accuracy. The message reflects warehouse execution outcomes versus requested quantities, including changes such as item shortages, substitutions, or cancelled lines.

How does PartnerLinQ use the EDI 945 Warehouse Shipping Advice?

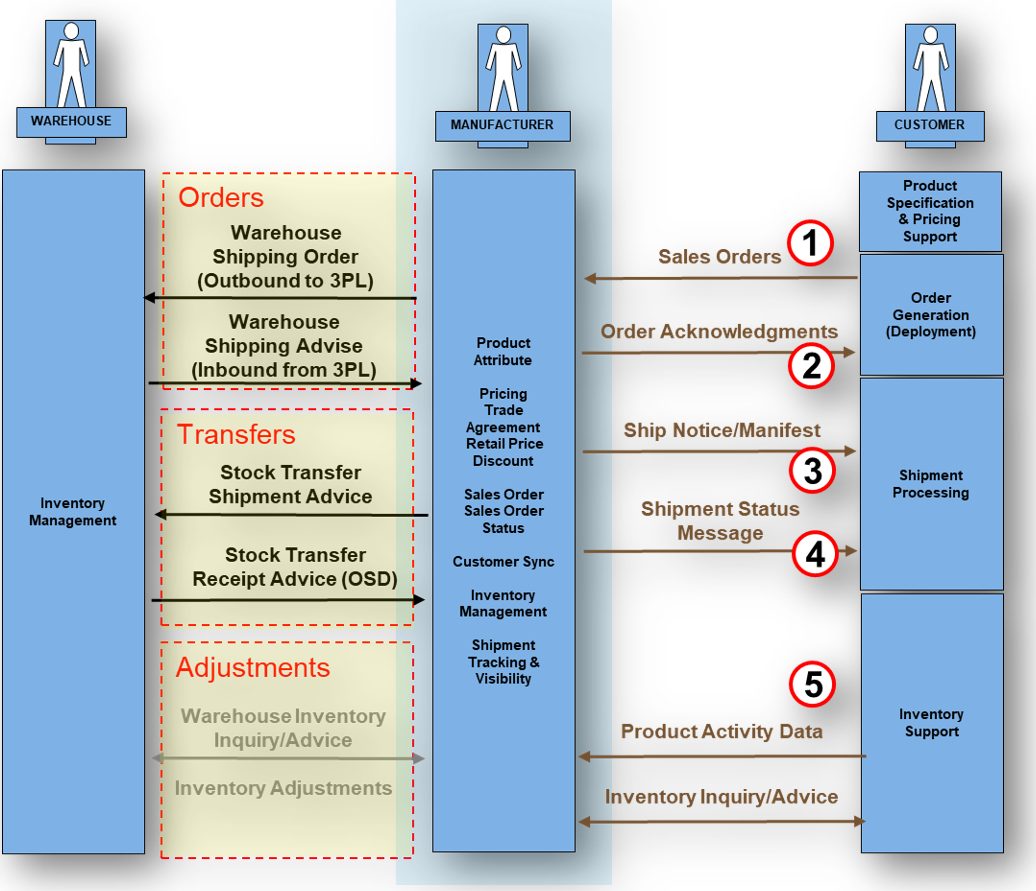

PartnerLinQ ingests inbound EDI 945 messages from warehouse and 3PL systems to validate fulfillment results, update order status, and trigger financial and logistics workflows.

PartnerLinQ maps the EDI 945 Warehouse Shipping Advice to the related EDI 940 Warehouse Shipping Order, compares requested and actual quantities, confirms transportation and pallet identifiers, and posts results to ERP, WMS, and visibility dashboards. This automated validation accelerates billing, improves inventory accuracy, and maintains synchronized order status.

PartnerLinQ processes inbound 945 messages from warehouse and 3PL systems to update supply chain visibility, reconcile order fulfillment, and support invoice creation.

PartnerLinQ evaluates the 945 against the original 940 Warehouse Shipping Order, validates identifiers and quantities, and updates system-of-record fulfillment status. The transaction supports flexible structures for shipment, order, pallet, and carton levels, enabling accurate, GS1‑aligned traceability and Smart Visibility reporting. PartnerLinQ supports full refresh and exception‑only methods, though recommends full refresh for data consistency.

What responses to the EDI 945 Warehouse Shipping Advice are expected/sent?

A  typical response to the EDI 945 Warehouse Shipping Advice is a Functional acknowledgments (997). to confirm receipt and syntax compliance and may include the Implementation Acknowledgement (999) in some regulated or high‑value supply chains. Some recipients leverage the EDI 945 in automation routines to generate transportation execution updates, invoicing steps, and shipment notifications to their partners.

typical response to the EDI 945 Warehouse Shipping Advice is a Functional acknowledgments (997). to confirm receipt and syntax compliance and may include the Implementation Acknowledgement (999) in some regulated or high‑value supply chains. Some recipients leverage the EDI 945 in automation routines to generate transportation execution updates, invoicing steps, and shipment notifications to their partners.

While EDI systems generally respond with Functional acknowledgments (997), ship notification and advance financial processing typically require advanced automation, automation available in PartnerLinQ. Integrating the EDI 945 with ERP and WMS platforms, allows for deeper automation, automation like closing orders, triggering shipment notifications and releasing invoices, automations that provide additional benefits long after integration has been completed.

What does the EDI 945 Warehouse Shipping Advice support?

Warehouse‑to‑seller  shipment confirmations such as EDI 945 Warehouse Shipping Advice support succinct identification of shipment units and the quantities shipped, pallet IDs (SSCCs), carton identifiers (GTINS), reference data and carrier details. The structure of the EDI accommodates UPCs, EPCs, AZNs, supports serialized traceability and RFID identifiers when desired or required by regulated or high‑value supply chains.

shipment confirmations such as EDI 945 Warehouse Shipping Advice support succinct identification of shipment units and the quantities shipped, pallet IDs (SSCCs), carton identifiers (GTINS), reference data and carrier details. The structure of the EDI accommodates UPCs, EPCs, AZNs, supports serialized traceability and RFID identifiers when desired or required by regulated or high‑value supply chains.

The EDI 945 also supports Platform Supply chains (PSCs), the modern equivalent of traditional supply chains. Entities that leverage digital platforms to connect producers, consumers, partners, and stakeholders, and connect with other digital platforms (PSCs). Third-party logistics (3PL), Fourth-party logistics (4PL), even Fifth-party logistics (5PL) operators who add layers to the logistics story by incorporating technology, managing increasingly complex sometimes global supply chain networks, often catering to online high‑value supply chain businesses.

What are the Key Features of the EDI 945 Warehouse Shipping Advice?

Key capabilities include:

- Shipment confirmation from the warehouse to the shipper (client/product owner)

- Alignment with the EDI 940 Warehouse Shipping Order, 856 (ASN), and 810 (Invoice)

- Multilevel granularity – shipment, order, pallet, and pack

- Support for SSCC‑based pallet and container identifiers

- Serialized traceability, EPC/RFID and GS1 barcode alignment

- Carrier, date, and transportation reference detail

What is the Purpose of the EDI 945 Warehouse Shipping Advice?

The primary purpose of the 945 is to provide a positive confirmation that a shipment has been completed and dispatched from a warehouse (often a third-party logistics provider or 3PL) to an end customer or buyer, while providing detailed information to reconcile actual shipped quantities against the shipment request. The transaction enables deep supply chain integration, accurate billing and inventory reduction, financial posting and invoicing, transportation orchestration, and complete fulfillment visibility.

What Information is Included in the EDI 945 Warehouse Shipping Advice?

The 945 includes:

- Shipment identifiers and warehouse order and external references

- Item identifiers (SKU, GTIN, lot, serial if present)

- Pallet and case identifiers (SSCC/EPC)

- Quantities shipped, cancelled, or substituted

- Ship‑to and ship‑from location details

- Carrier, transportation, and delivery references

- Dates of execution and release

What are the Essential Components of the EDI 945 Warehouse Shipping Advice?

Essential components include:

| Element | Purpose |

|---|---|

| ST | Message header and control number |

| W06 | Shipment identification and shipment type indicator |

| N1 | Party identification for warehouse, ship‑to, ship‑from |

| G62 | Shipment date information |

| W27 | Carrier details |

| MAN | Marks and Numbers (SSCC/EPC) |

| W12 | Item detail including quantity and reference (SKU, GTIN, batch/lot, serial) |

| W03 | Totals to automate reconciliation of the shipment |

| SE | Message trailer and control reference |

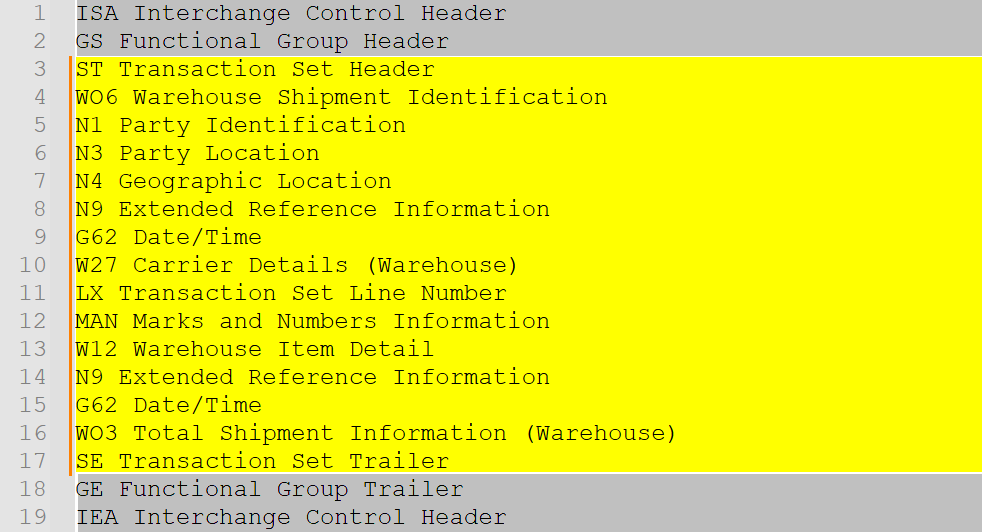

What are the Common Segments Included in the EDI 945 Warehouse Shipping Advice?

Common segments include:

| Segment | Description |

|---|---|

| ST | Transaction header |

| W06 | Warehouse shipment identification |

| N1/N3/N4 | Party and address detail for warehouse, ship-to, ship-from |

| N9 | Reference details such as PO or BOL |

| G62 | Critical dates such as ship date |

| W27 | Carrier and transportation details |

| LX/MAN | Marks, carton, and pallet IDs |

| W12 | Line item shipped quantities |

| W03 | Total quantities and weight |

| SE | Transaction footer |

What Status Codes are used with the EDI 945 Warehouse Shipping Advice?

Status codes in the Warehouse Shipping Advice (945) are used to notify the seller that a shipment was made on their behalf and to provide information concerning the shipment, shipment changes, cuts, substitutions, changes (Updates), cancellations or partial cancellations; typical values include:

- F – Full detail shipment

- X – Exceptions only

- 2 – Update

- C – Cancellation

- AX – Partial cancellation

What Reason Codes are used with the EDI 945 Warehouse Shipping Advice?

Reason codes explain shipment reductions, substitutions, timing differences, or warehouse adjustments. Structures exist within the EDI 945 Warehouse Shipping Advice to report a reason for change in the shipping date, "cuts", and substitution, and just like the Warehouse Shipping Order (940), the seller's product number and traceability information can be used with the seller's GTIN.

Examples include:

- Transportation Adjustment (Cuts) eliminates excess transportation costs

- Short pick due to stock unavailability - Physical Inventory Shortage

- Shipping Date Code tells a depositor why shipment was delayed

- Substitution for approved alternate item

- Carrier or dock delay adjustments

- Coupon Adjustments

What Use Cases does the EDI 945 Warehouse Shipping Advice support?

The EDI 945 Warehouse Shipping Advice transaction set is primarily designed for warehouse-to-depositor communications in supply chain fulfillment, particularly in scenarios involving third-party logistics (3PL) providers (remote warehouses)

Considering the primary design logic, the EDI 945 has evolved into a too that delivers a broad range of value to a significant assortment of Industries and Partners:

| Use Case | Description | Typical Workflow Industries/Partners |

|---|---|---|

| Shipment Confirmation in 3PL Fulfillment of Direct-to-Store, Direct-to-Consumer | A 3PL or warehouse notifies the seller (depositor) that goods have been shipped to the end customer, providing details like quantities, dates, and carrier info to close the fulfillment loop. | Follows EDI 940 (Warehouse Shipping Order); may precede EDI 856 (Advance Ship Notice), used in retail, e-commerce; Sellers and 3PLs like Magaya or Unique Logistics. |

| Quantity Reconciliation and Inventory Updates | Reconciles actual shipped items against the original order, highlighting shortages, overages, or substitutions to update inventory records and prevent discrepancies. | Used post-pick/pack to adjust seller's stock levels; integrates with manufacturing, distribution; depositors and remote warehouse systems for real-time visibility. |

| Multi-Partner Supply Chain Coordination | Facilitates communication across trading partners (e.g., suppliers, carriers) by sharing shipment details, ensuring all parties have accurate status for coordinated logistics. | Part of a broader EDI flow including EDI 810 (Invoice) for billing after confirmation. Any 3PL-heavy sector; Multiple partners in global supply chains. |

| Triggering Downstream Actions like ASN or Invoicing | Provides data to generate advance ship notices or initiate invoicing, automating the transition from warehouse ops to customer delivery and payment. | Supports sales order reconciliation from warehouses, distribution, & wholesale partners. |

Use cases such as these streamline B2B operations by reducing manual interventions, minimizing errors, and enhancing traceability in warehouse-based shipping.

What are the Benefits of the EDI 945 Warehouse Shipping Advice?

The EDI 945 transaction streamlines warehouse-to-depositor communication by automating shipment confirmations, leading to operational improvement across traditional, regulated, and high‑value supply chains.

Benefits include:

- Increases warehouse throughput by leveraging automation

- Increases inventory integrity and audit readiness

- Promotes accurate financial posting and billing

- Facilitates invoicing and ASN generation

- Improves the customer notification process

- Reduces manual data entry and errors

- Improves multi-party coordination

- Enhances Operational Visibility

- Reduces manual reconciliation

How efficient is the EDI 945 Warehouse Shipping Advice?

Automation that includes the EDI 945 reduces cycle time between warehouse operations, billing, and transportation. When paired with exception reporting, notifications and alerting, the EDI 945 Warehouse Shipping Advice ensures that discrepancies surface prior to invoicing, thereby reducing cycle times including DSO (Days Sales Outstanding)

Automation that includes the EDI 945 reduces cycle time between warehouse operations, billing, and transportation. When paired with exception reporting, notifications and alerting, the EDI 945 Warehouse Shipping Advice ensures that discrepancies surface prior to invoicing, thereby reducing cycle times including DSO (Days Sales Outstanding)

How Compliant is the EDI 945 Warehouse Shipping Advice?

The EDI 945 Warehouse Shipping Advice aligns with X12 v4010 standards, GS1 SSCC practices, and AS2 communication protocols, The 945 supports global warehouse networks and industry audit controls.

What is the Format of the EDI 945 Warehouse Shipping Advice?

The EDI 945 Warehouse Shipping Advice is a standardized X12 transaction aligned with and in support of warehouse execution schemes and systems. Aligned with the EDI 940 Warehouse Shipping Order, the 945 supports , pallet IDs (SSCCs), carton identifiers (GTINS), reference data carrier details and traceability elements.

How Accurate is the EDI 945 Warehouse Shipping Advice?

Accuracy depends on the sender and receivers’ ability to synchronize unique identifiers, (SSCCs, EPCs, GTINs, SKUs, GTIN, batch/lot, and serial numbers), the timely execution and posting of warehouse transaction, and adherence to standards. Tools such as PartnerLinQ aid in this process by validating structure, identifiers, and quantities during processing.

What are the Limitations of the EDI 945 Warehouse Shipping Advice?

Typical limitations stem from warehouse system capability. Exception‑only reporting requires careful state management. Identification consistency, the use of unique identifiers improves accuracy, visibility and traceability.

Typical limitations stem from warehouse system capability. Exception‑only reporting requires careful state management. Identification consistency, the use of unique identifiers improves accuracy, visibility and traceability.

Are Guidelines & Sample Files for the EDI 945 Warehouse Shipping Advice available?

Yes. PartnerLinQ provides sample EDI 945 Warehouse Shipping Advice Transaction and implementation guides through its Support and Guideline Management Team.

Sample EDI 945 implementation guides illustrate both inbound and outbound flows, segment layouts, and valid data examples and support testing and partner onboarding. Customized specification documents for use in on boarding and technical development are available upon request.

PartnerLinQ provides:

- EDI 945 Warehouse Shipping Advice transaction implementation guide

- Sample payloads

- Qualification and testing maps

- Error handling and best-practice notes

What are the Basic Questions for EDI Integration with the EDI 945 Warehouse Shipping Advice?

Key questions include:

- What is the general direction of the transaction?

- Are they Inbound or outbound to another party?

- Are there more than one trading partner exchanging Warehouse Shipping instruments (940/945) in a Multi-Partner Supply Chain

- Is there automation? (an internal systems trigger) Or are EDI 945 business message transactions triggered manually?

- Are there other interested parties?

- What transactions might these interested parties be a party to?

- Is a response to the transaction a timed event? Are notifications involved/needed?

- What response to the transaction is expected or sent?

- Are responses automatically triggered? (an internal systems trigger) Or do transactions require human intervention?

- Are other transactions triggered in response?

- How are changes to the business message managed today?

- Is there automation in place (an internal systems trigger) or are changes to the Warehouse Shipping Advice (945) triggered manually?

- Which ERP/WMS systems participate?

- Will SSCC pallet labeling be exchanged?

- How are substitutions governed?

What Business Level Workflow does the EDI 945 Warehouse Shipping Advice support?

Typical workflow:

- Initiation: The depositor sends an EDI 940 Warehouse Shipping Order to the warehouse, specifying items, quantities, and shipping instructions to fulfill customer orders.

- Processing: The warehouse receives the EDI 940, picks the items, packs them, and prepares the shipment, including any carrier arrangements.

- Shipment: Once the shipment leaves the warehouse, the warehouse generates and transmits the EDI 945 to the depositor, detailing actual shipped quantities, variances, shipment date, carrier info, tracking numbers, and packaging details.

- Receipt The depositor receives the EDI 945

- Acknowledgment: The depositor sends an EDI 997 Functional Acknowledgment back to the warehouse to confirm receipt and processing of the EDI 945.

- Validation: The depositor validates the EDI 945 against the original order for accuracy, often via automated ERP integration.

- Reconciliation and Updates: The depositor reconciles discrepancies (e.g., shortages or substitutions), updates inventory records and adjusts sales orders accordingly.

- Downstream Activities: The EDI 945 data triggers further steps, such as generating an EDI 856 Advance Ship Notice to the end customer or initiating EDI 810 invoicing. What are the Best Practices for using the EDI 945 Warehouse Shipping Advice?

| Best Practice | Benefit |

|---|---|

| Use full refresh method | Ensures data consistency |

| Validate SSCC identifiers | Improves traceability |

| Automate reconciliation | Improves processing time and accuracy |

| Align code lists with partners | Reduces exception handling |

What Transactions are associated with the EDI 945 Warehouse Shipping Advice?

| Transaction | Role |

|---|---|

| 810 | Invoice following shipment confirmation |

| 850 | Purchase Order |

| 856 | Advance Ship Notice |

| 940 | Warehouse Shipping Order Request |

| 943 | Warehouse Stock Transfer Shipment Advice |

| 944 | Warehouse Stock Transfer Receipt Advice |

| 945 | Warehouse Shipping Confirmation |

| 947 | Warehouse Inventory Adjustment Advice |

| 997 | Functional Acknowledgment |

| 999 | Implementation Acknowledgment |

Footnotes

1. PartnerLinQ Warehouse Shipping Advice Guidance.

Explore Our Integration Solutions

PartnerLinQ Integration Solutions

Connect Everything. Integrate Intelligently.

Future-Proof Your Business with Composable, AI Powered Connectivity.