What is the EDI 944 Warehouse Stock Transfer Receipt Advice?

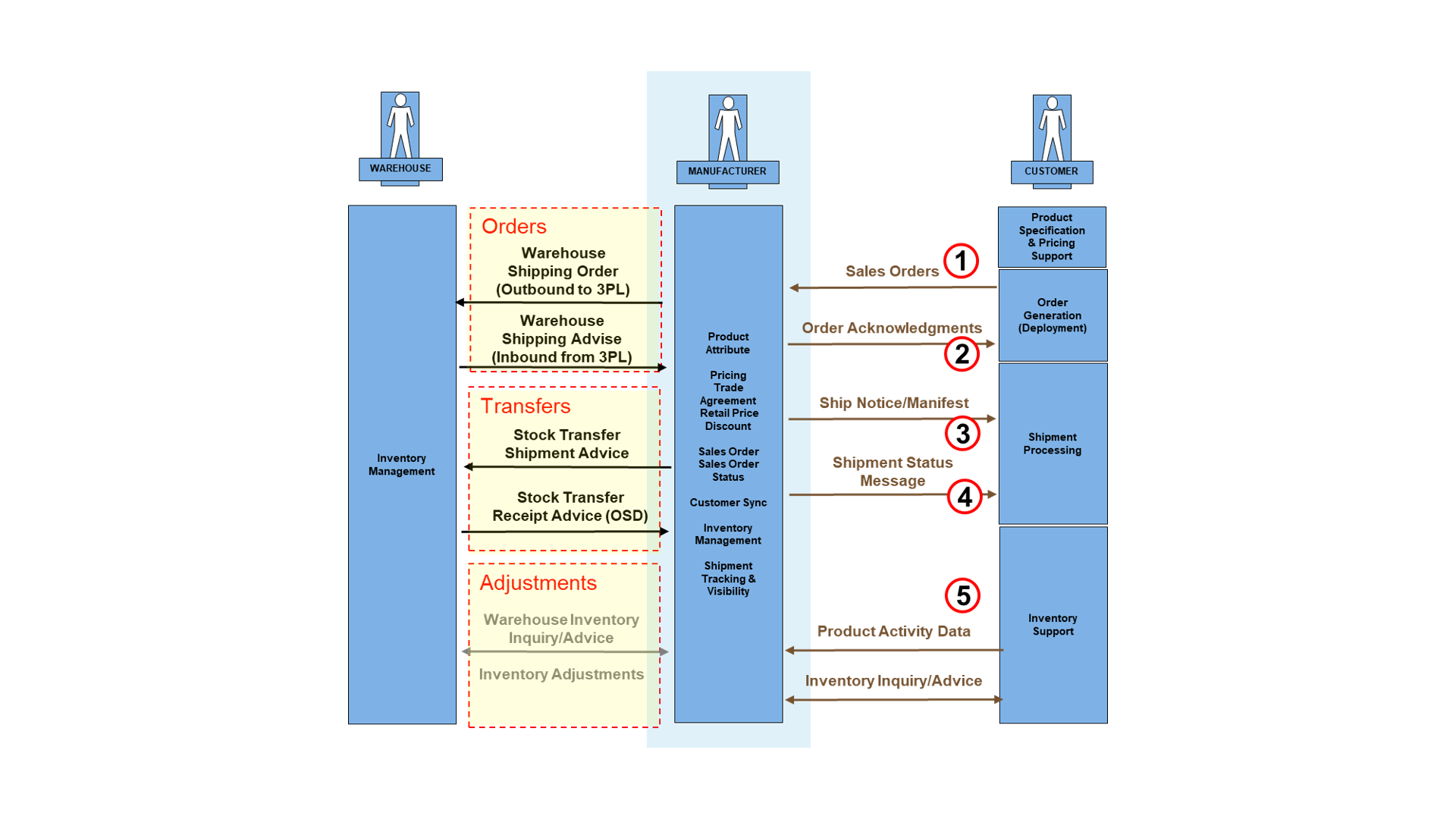

The EDI 944 Warehouse Stock Transfer Receipt Advice is used to confirm that inventory shipped from the ‘origin’ (facility) has been physically received into the ‘destination’ warehouse.

The EDI 944 message communicates detail at the pallet, case, or item level and in regulated, high value or serialized supply chains, the 944 provides critical traceability for lot, batch, expiration, and SSCC/EPC identifiers. It validates received quantities against expected values received in the EDI 943 Warehouse Stock Transfer Shipment Advice and aids in processing those details accordingly.

The Warehouse Stock Transfer Receipt Advice (944) supports use of the GS1 barcode and Electronic Product Code / Radio Frequency Identification (EPC/RFID) data carriers as well as product serial number identification.

When complemented with the GS1 Serial Shipping Container Code (SSCC), used to identify the logistics unit (pallet, carton, etc.), both depositors and warehouses benefit from the exchange of the Warehouse Stock Transfer Shipment Advice (943) and Warehouse Stock Transfer Receipt Advice (944)transactions.

The  information contained in the Warehouse Stock Transfer Receipt Advice (944) provides the depositor with information to record and adjust product inventory levels at the public warehouse and the warehouse operator benefits by easily aligning received units against the expected units, managing dock throughput more efficiently, capturing inbound variances, and confirming the receiving warehouse has taken custody of the inventory and can report accurately on its status.

information contained in the Warehouse Stock Transfer Receipt Advice (944) provides the depositor with information to record and adjust product inventory levels at the public warehouse and the warehouse operator benefits by easily aligning received units against the expected units, managing dock throughput more efficiently, capturing inbound variances, and confirming the receiving warehouse has taken custody of the inventory and can report accurately on its status.

When used properly and transmitted on a timely basis, The EDI 944 transaction supports stock transfers across distribution centers, public warehouses, 3PL fulfillment nodes, consolidation hubs, and forward-deployed strategic inventory points strengthening operational accuracy, accelerating posting of inventory records, and enabling timely financial and supply chain visibility across connected facilities.

How does PartnerLinQ use the EDI 944?

PartnerLinQ uses the Warehouse Stock Transfer Receipt Advice (944) to confirm the receipt of a stock transfer when a transfer shipment from a depositor is received by the public warehouse.

Typically observed as being sent from the receiving warehouse to an initiator (e.g., a manufacturer, retailer, or another warehouse), the primary purpose of the Warehouse Stock Transfer Receipt Advice (944) is to assure the depositor a transfer has been made and the inventory can be updated accordingly.

The Warehouse Stock Transfer Receipt Advice (944) verifies the stock transfer shipment, often initiated via Warehouse Stock Transfer Shipment Advice (943) received at the destination warehouse. PartnerLinQ processes inbound 944 messages from warehouses and 3PLs to confirm receipt of inventory, then:

- Validates receipt quantities against the corresponding 943 transfer advice

- Reconciles lot/serial/expiration data where applicable

- Triggers inventory posting or availability updates in ERP and WMS systems

- Records discrepancies and exceptions for automated workflow routing

- Links shipment references (BOL, PRO, tracking, SSCC codes) back to the originating transfer

- Updates decision-intelligence dashboards and operational visibility widgets

- Maintains audit history for internal compliance and financial controls

PartnerLinQ facilitates the Warehouse Stock Transfer Receipt Advice (944) for senders and recipients and fully supports both full detail and exceptions-only models recognizing the dependency on the partner’s technical maturity and data strategy. The PartnerLinQ platform enhances traceability and inventory integrity across multi-node networks, while supporting regional balancing, cross-dock replenishment, and strategic staging for omni-fulfillment programs.

What responses to EDI 944 Warehouse Stock Transfer Receipt Advice are expected or sent?

While the 944 completes the 943-to-944 stock transfer lifecycle however most trading partners will expect other EDI transactions in response to or following the EDI 944 Warehouse Stock Transfer Receipt Advice which fall under 2 headings

- 997 / 999 Functional Acknowledgment (structure/receipt)

- System acknowledgment / posting event

- Occasional ‘Exception’ workflows - triggered by variances

- Suggested ‘Movement’ workflows - triggered by supply or demand influences

Depositors generally respond to (acknowledge) the EDI 944 Warehouse Stock Transfer Receipt Advice to confirm transaction receipt and variances. The EDI 997 and EDI 999, are a part of ‘response processing’ and provide syntax acknowledgments when partners agree to exchange them, and most do.

The Functional Acknowledgment (997) is an ANSI X12 EDI transaction set that represents industry’s best practice and is automatically generated by modern EDI software. The Implementation Acknowledgment (999) is an ANSI X12 transaction set designed to provide detailed feedback on the acceptance or rejection of received EDI transactions. Unlike the 997, which only indicates syntactical validity, the Implementation Acknowledgment (999) also evaluates compliance against published implementation guides.

There is a tendency among partners to have ‘exception’ workflows in this space to (A) confirm inventories by exchanging the EDI 846 Inquiry/Advice and (B) report changes to inventories by exchanging the 947 Inventory Adjustment transaction.

Lastly, there are ‘movement’ workflows. Events, triggered by supply, demand, even influences resulting from a positive indication from testing that advised the depositor that a selected inventory can be moved into a saleable position. The depositor then instructs the warehouse to ‘move’ inventory into a ‘saleable’ inventory position which might very well be the case with a returned product or a product that has been cleared for sale. The depositor might use the EDI 940 Warehouse Shipping Order transaction or an EDIFACT HANMOV (Cargo/Goods Handling and Movement Message)for that purpose.

What does the EDI 944 Warehouse Stock Transfer Receipt Advice support?

- Confirmation of inventory receipt into warehouse custody

- Discrepancy reporting for over/short/damaged units

- Internal network supply chain synchronization

- Inventory posting and on-hand visibility updates

- Compliance with regard to regulated products

- Carton / pallet / item receipt verification

- Serialized and lot-controlled goods processing

- SSCC and EPC/RFID value capture

What are the Key Features of the EDI 944 Warehouse Stock Transfer Receipt Advice?

| Feature | Value |

|---|---|

| Confirmation of receipt | Establishes authoritative receipt record |

| Variance reporting | Logs shortages, overages, damages, and substitutions |

| Serial and lot integrity | Preserves trace and audit readiness |

| Full vs exceptions-only | Supports complete detail or delta reporting |

| Cross-system alignment | Synchronizes ERP, WMS, and visibility environments |

| High-velocity inbound support | Enables rapid receiving and staging |

What is the Purpose of the EDI 944 Warehouse Stock Transfer Receipt Advice?

The EDI 944 validates and records inventory receipt from a transfer shipment, enabling accurate warehouse availability, financial posting, and traceable stock movement across network nodes. Information that includes:

| Category | Detail |

|---|---|

| Transfer references | Shipment ID, transfer number, BOL, tracking |

| Locations | Ship-from facility, receiving warehouse, depositor |

| Item / packaging detail | SKU, UOM, pallet and case identifiers |

| Lot / expiration / serial | When required for trace or compliance |

| Quantities | Actual received vs expected |

| Variance detail | Over/short/damaged recording |

| Totals | Weight, volume, handling metrics |

What Information is Included in the EDI 944 Warehouse Stock Transfer Receipt Advice?

| Segment | Key Element | Meaning |

|---|---|---|

| W0701 | Receipt type | Full receipt / partial / exception only |

| N1 – N4 | Party identifiers | Defines depositor, ship-from, warehouse |

| N9 Refs | BOL (BM) / tracking numbers (2i) | Connects physical shipment to receipts |

| G62 01 | Date qualifiers | Receipt and available-to-use timestamps |

| W2003 | Variance code | Over/short/damage classification |

| W27 | Totals | Confirms final received quantities |

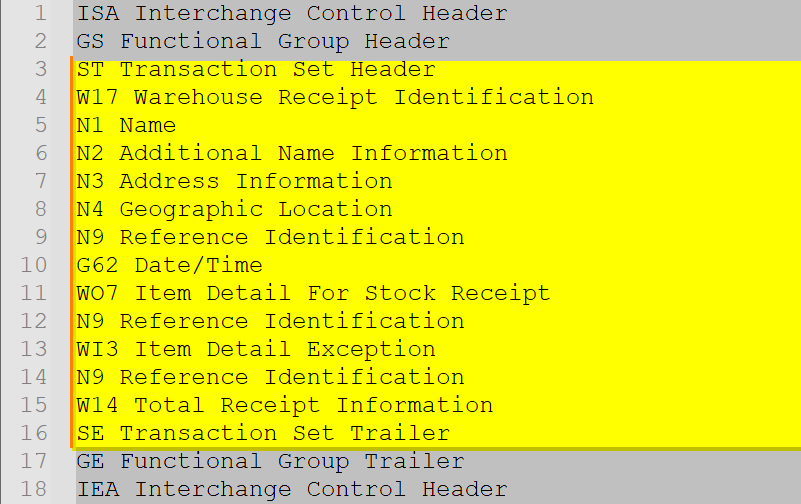

What are the Essential Components of the EDI 944 Warehouse Stock Transfer Receipt Advice?

| Segment | Description |

|---|---|

| ST | Transaction header / control identifiers |

| W07 | Receipt information and control flags |

| N1 - N4 | Ship-from, receiving party, depositor information |

| N9 | Reference IDs (BOL, PRO, tracking) |

| G62 | Dates and times (receipt and posting events) |

| LX | Line loop start |

| W01 | Item detail (SKU, qty, packaging) |

| G69 | Item description |

| W20 | Receipt discrepancy detail |

| W27 | Totals and summary warehouse receipt information |

| SE | Transaction trailer |

What are the Common Segments Included in the EDI 944 Warehouse Stock Transfer Receipt Advice?

- ST / SE envelope control

- W07 receipt instruction/control

- N1 party and warehouse addressing

- N9 reference numbers

- G62 receiving date/time qualifiers

- W01 item-level detail

- W20 discrepancy detail

- W27 total receipt metrics

What Status Codes are used with the EDI 944 Warehouse Stock Transfer Receipt Advice?

| Qualifier | Description |

|---|---|

| C | Customer Return - Full Detail |

| F | Full Detail |

| J | Original Transaction |

| P | Production Receipt, Full Detail |

| X | Exceptions Only |

The W1701 Reporting Code segment provides key details about the receipt of stock at the public warehouse and uniquely identifies the receipt transaction.

What Reason Codes are used with the EDI 944 Warehouse Stock Transfer Receipt Advice?

Interestingly unlike most X12 documents there are levels of ‘reason codes’ available, each describing a different condition.

Receiving Condition Code (W1301) - Codes that designate the physical condition or status of units received:

| Qualifier | Description |

|---|---|

| 05 | Incorrect Product |

| 03 | Quantity Over |

| 02 | Quantity Short |

| 01 | Damaged Product or Container |

Damage Reason Code (W1305) - Codes identifying the specific reason for exception

| Qualifier | Description |

|---|---|

| LS | Load Shift |

| IL | Improper Loading |

| HD | Hidden Damage (Suspected or Actual) |

| DP | Defective Pallets or Slip Sheets |

| DL | Damage Loading |

What Use Cases does the EDI 944 Warehouse Stock Transfer Receipt Advice support?

| Use Case | Supported Business Processes |

|---|---|

| Stock Transfer Confirmation | Inventory planning, forecasting, and replenishment; dock scheduling and labor planning; receiving preparation. |

| Customer Return Notification | Return goods handling; reverse logistics coordination; inventory adjustments. |

| Shipment Tracking and Dock Scheduling | Receiving preparedness and transit visibility for goods in motion. |

| Inter-Warehouse Stock Movement / DC Balancing | Stock redistribution; location updates; real-time inventory synchronization across facilities. |

| Inventory Record Updates | Automation for reconciliation of shipped vs. received quantities; reduction in manual errors. |

| Regional Replenishment for Retail, Convenience, and Grocery Networks | Demand-driven replenishment; route optimization for perishable goods; multi-site inventory leveling. |

| 3PL Fulfillment for Direct-to-Store and Direct-to-Consumer Models | Order fulfillment orchestration; last-mile preparation; integration with e-commerce platforms. |

| Cold-Chain and Regulated Supply Chain Execution with Special Handling | Temperature logging; compliance certification; chain-of-custody documentation. |

| Export Logistics with Sealed Pallets and Serial Control | Export compliance; serial number validation; pallet-level tracking for global handoffs. |

| Vendor-Managed Inventory in Public Warehousing | VMI replenishment cycles; space allocation in multi-tenant facilities; automated threshold alerts. |

| Cross-Dock and Flow-Through Environments | Cross-dock sorting; flow-through labeling; minimal dwell-time processing. |

| Omni-Channel Allocation and Staging | Channel-specific inventory splitting; staging for blended orders; real-time availability syncing. |

| DC to DC Transfers | Inter-DC routing; consolidation of partial loads; capacity planning across networks. |

- Public warehouse and 3PL inbound operations

- Spare parts, automotive, aftermarket transfers

- CPG, food, beverage, pharma inbound flows

- Cross-dock and staging points

- Multi-node retail networks

How efficient is the EDI 944 Warehouse Stock Transfer Receipt Advice?

The 944 shortens the lag between physical receipt and system availability, accelerating fulfillment readiness and reducing aging inventory blind spots.

How Compliant is the EDI 944 Warehouse Stock Transfer Receipt Advice?

- ANSI X12 944 v4010

- GS1 SSCC and EPC/RFID standards

- USDA / FDA / FSMA environments (when applicable)

- Standard EDI control envelope and acknowledgments

What is the Format of the EDI 944 Warehouse Stock Transfer Receipt Advice?

The EDI 944 uses the ANSI X12 Warehouse Stock Transfer Receipt Advice for digital stock transfer shipments and shipments in transit to a warehouse, warehouse receipt, and shipment notification.

How Accurate is the EDI 944 Warehouse Stock Transfer Receipt Advice?

Accuracy depends on synchronized master data, identifiers, location codes, and partner code lists; validation of ST/SE control numbers and mandatory content supports processing integrity.

- Synchronized item and location master data

- SSCC and serial validation when used

- Strong discrepancy handling processes

What are the Limitations of the EDI 944 Warehouse Stock Transfer Receipt Advice?

Adoption depends on partner maturity regarding their business processes and WMS, and agreement on refresh versus cancel/replace strategy for change management. Advanced capabilities such as handling Batch/lot or advanced serialized might limit adoption in certain high value or regulated supply chains.

- Exceptions-only mode requires robust discrepancy automation

- Warehouse must support timely data capture

- Serial/Lot granularity requires mature labeling practices

Are Guidelines & Sample Files for the EDI 944 Warehouse Stock Transfer Receipt Advice available?

Yes. Sample EDI 944 Warehouse Stock Transfer Receipt Advice and implementation guides that support testing and partner onboarding are available through PartnerLinQ.

Sample EDI 944 implementation guides illustrate both inbound and outbound flows, segment layouts, and valid data examples and support testing and partner onboarding. Customized specification documents for use in on boarding and technical development are available upon request.

PartnerLinQ provides:

- EDI 944 Warehouse Stock Transfer Receipt Advice implementation guide

- Sample payloads

- Qualification and testing maps

- Error handling and best-practice notes

What are the Basic Questions for EDI Integration with the EDI 944 Warehouse Stock Transfer Receipt Advice?

- Are there Samples and Specs available?

- What EDI version and standard will be used?

- What is the general direction of the transaction?

- Are they Inbound or outbound to another party?

- Is this a full-detail or exceptions-only model?

- What response is expected or sent to the transaction?

- Is a warehouse pre-receive required?

- Are there samples and specs of the response transaction available?

- Are responses and changes automatically triggered? (an internal systems trigger)

- Do transactions require human intervention?

- Are there other interested parties?

- What transactions might these interested parties be a party to?

- Are there order or shipment types that need to be tracked or handled differently?

- Are there any business rules that should be considered when processing EDI 944 Warehouse Stock Transfer Receipt Advice? (e.g., invalid/missing item or customer identification number)

- Do Batch or Lot numbers need to be tracked? Is there serialization?

- Will SSCC and EPC/RFID be captured?

- Which date qualifiers are mandatory?

- Are lot and expiration details required?

- Are products consolidated and presented as single line items, or are sublines involved?

- How are changes to the EDI 944 Warehouse Stock Transfer Receipt Advice business message transaction today?

- What triggers inventory posting events?

- How are discrepancies reconciled and reported?

- How are financial adjustments tracked?

- What is the master data source for item and location codes?

- How are discrepancies resolved?

What Business Level Workflow does the EDI 944 Warehouse Stock Transfer Receipt Advice support?

- Initiation: The Transfer is initiated, and the depositor sends an EDI 943 Warehouse Stock Transfer to the warehouse, identifying items, quantities, and shipping details.

- Processing: The warehouse receives the EDI 943 and plans the inbound logistics flow before the trailer arrives.

- Shipment: Once the shipment arrives at the warehouse, the warehouse team receives the shipment, begins ‘put-a-way’ processing, generates and transmits the EDI 944 to the depositor, detailing the items and quantities received, variances, and packaging details within the specified period

- Receipt The depositor receives the EDI 944

- Acknowledgment: The depositor sends an EDI 997 Functional Acknowledgment back to the warehouse to confirm receipt and process the contents of the EDI 944, updating inventories.

- Validation: The depositor validates the EDI 944 against the original EDI 943 for accuracy, often via automated ERP integration.

- Reconciliation and Updates: The depositor reconciles discrepancies (e.g., exceptions, Over, Short, & Damaged (OSD)), updates inventory records and adjusts inventory and locations accordingly.

- Downstream Activities: The EDI 943/944 data may trigger additional steps, steps such as generating an EDI 947 to notify the depositor of discrepancies like concealed damages or shortages uncovered during ‘put-a-way.’

What are the Best Practices for using the EDI 944 Warehouse Stock Transfer Receipt Advice?

| Practice | Benefit |

|---|---|

| Confirm 997/999 exchanges | Ensures message acceptance |

| Process 943 before freight arrives | Like the ASN, EDI 943 Warehouse Stock Transfer Shipment Advice should be automated to ensure that when it is sent it is processed and the receiving warehouse has time for dock planning. |

| Utilize a ‘Change-by-Refresh’ process | PartnerLinQ suggests a ‘change by refresh’ process for partners who expect Warehouse Shipping Order to change and anticipate the use of change or replacement orders. ‘Change-by-Refresh’ ensures data consistency and reduces state drift. |

| Validate SSCC and Item Master Data | Ensuring scan accuracy is vital to electronic processing, automation at this level begins with the timely exchange of key data elements including item catalog data. SSCCs can and should be validated against the EDI 943 Warehouse Stock Transfer Shipment Advice to identify missing pallet items at the very least. |

| Record discrepancies | Strengthen audit, claims, and chargeback workflows by enabling the W13. |

| Automate WMS posting | Accelerates inventory available for shipments |

| Include BOL and SSCC tracking | Strengthens traceability and appointment setting |

| Monitor acknowledgments and exceptions | Improves security, trust and reliability between depositors and warehouses. |

What Transactions are associated with EDI 944 Warehouse Stock Transfer Receipt Advice?

| Transaction | Role |

|---|---|

| 850 | Purchase Order |

| 856 | Advance Ship Notice |

| 940 | Warehouse Shipping Order |

| 943 | Warehouse Stock Transfer Shipment Advice |

| 945 | Warehouse Shipping Confirmation |

| 947 | Warehouse Inventory Adjustment Advice |

| 997 | Functional Acknowledgment |

| 999 | Implementation Acknowledgment |

Footnotes

- PartnerLinQ EDI Warehouse Execution Standards

- X12 v4010 EDI 944 guideline notes

- GS1 SSCC / EPC traceability references

- PartnerLinQ stock transfer lifecycle documentation

Explore Our Integration Solutions

PartnerLinQ Integration Solutions

Connect Everything. Integrate Intelligently.

Future-Proof Your Business with Composable, AI Powered Connectivity.