What is the EDI 846 Inventory Inquiry/Advice Transaction?

The EDI 84 6 Inventory Inquiry/Advice transaction provides a standardized mechanism for communicating inventory status between trading partners. The EDI communicates product inventory levels between trading partners. It enables sellers, warehouses, and buyers to exchange real-time data about available stock, reserved quantities, and replenishment opportunities. It allows buyers, sellers, and warehouses to share accurate product availability and stock details, reserve quantities, and replenishment opportunities. The 846 supports both inquiries (asking for inventory information) and advices (reporting current inventory positions).

6 Inventory Inquiry/Advice transaction provides a standardized mechanism for communicating inventory status between trading partners. The EDI communicates product inventory levels between trading partners. It enables sellers, warehouses, and buyers to exchange real-time data about available stock, reserved quantities, and replenishment opportunities. It allows buyers, sellers, and warehouses to share accurate product availability and stock details, reserve quantities, and replenishment opportunities. The 846 supports both inquiries (asking for inventory information) and advices (reporting current inventory positions).

How does PartnerLinQ use the 846 Transaction?

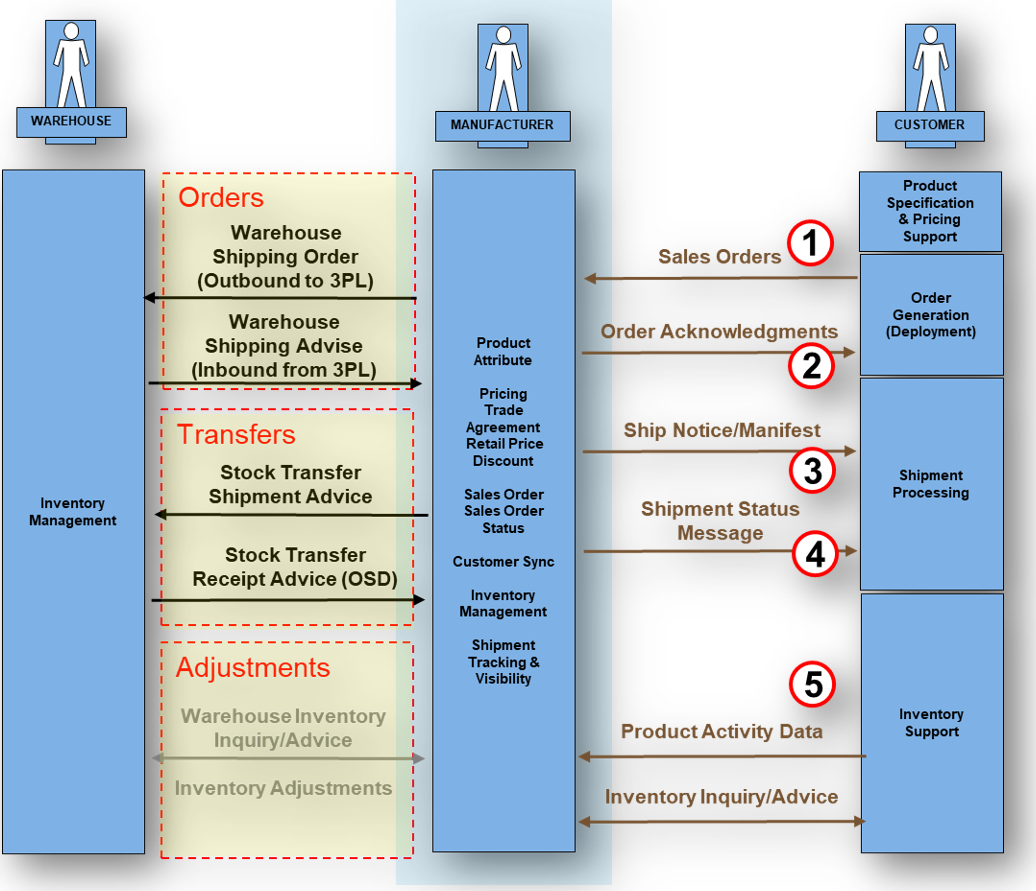

PartnerLinQ leverages the 846 Inventory Inquiry/Advice to facilitate seamless information exchange between warehouses, suppliers, distributors, retailers. It uses the 846 to synchronize real-time inventory data across the supply chain, enhancing visibility, reducing manual processes, and minimizing carrying costs between trading partners - buyers, sellers, and warehouses. The 846 facilitates visibility into available stock by lot, batch, or location and can also be used internally by a manufacturer to coordinate inventories between divisions, warehouses, suppliers, and distributors. PartnerLinQ uses the 846 to synchronize inventory data between internal systems and trading partners, this digital supply chain synchronization improves planning and accuracy while reducing overstock condition, fulfillment errors, and financial misstatements.

leverages the 846 Inventory Inquiry/Advice to facilitate seamless information exchange between warehouses, suppliers, distributors, retailers. It uses the 846 to synchronize real-time inventory data across the supply chain, enhancing visibility, reducing manual processes, and minimizing carrying costs between trading partners - buyers, sellers, and warehouses. The 846 facilitates visibility into available stock by lot, batch, or location and can also be used internally by a manufacturer to coordinate inventories between divisions, warehouses, suppliers, and distributors. PartnerLinQ uses the 846 to synchronize inventory data between internal systems and trading partners, this digital supply chain synchronization improves planning and accuracy while reducing overstock condition, fulfillment errors, and financial misstatements.

- Aligns warehouse stock levels with ERP and order management systems.

- Reduces manual reconciliation through automated event-driven updates.

- Supports both inbound (from warehouses) and outbound (to customers) flows.

- Improves supply-chain visibility across suppliers, 3PLs, and retailers.

What responses to the EDI 846 Inventory Inquiry/Advice are expected/sent?

Responses may include:

- EDI 997 Functional Acknowledgment confirming receipt.

- EDI 947 Warehouse Inventory Adjustment Advice for subsequent adjustments.

- Internal alerts or dashboards triggered in PartnerLinQ’s Smart Visibility console.

What does the EDI 846 Inventory Inquiry/Advice support?

The transaction supports:

- Inquiry about available inventory from any trading partner.

- Advice on stock balances, lots, and batch information.

- Synchronization between distribution centers and eCommerce systems.

- Cross-enterprise updates for omnichannel fulfillment.

What are the Key Features of the EDI 846 Inventory Inquiry/Advice?

- Multi-location and batch/lot visibility.

- Automatic updates via PartnerLinQ connectors (AS2, SFTP, API).

- Incremental and full inventory reporting modes.

- Support for GLN (Global Location Number) identifiers.

- ISO 8601 timestamps and GS1 compliant structure.

- Compatible with ERP systems such as SAP, Microsoft Dynamics 365, Oracle, and Infor.

What is the Purpose of the EDI 846 Inventory Inquiry/Advice?

To maintain accurate, real-time inventory data among partners and internal systems — enabling efficient procurement, replenishment, and logistics operations.

What Information is Included in the EDI 846 Inventory Inquiry/Advice?

- Header information (transaction purpose, control number, date/time).

- Location identifiers (ship-from, ship-to, warehouse).

- Product identifiers (SKU, UPC, GTIN, batch, or lot).

- Quantity details (on-hand, available, allocated).

- Optional pricing, currency, and lead-time data.

What are the Essential Components of the EDI 846 Inventory Inquiry/Advice?

| Segment | Segment - Element ID | Description | PartnerLinQ Notes |

|---|---|---|---|

| ST | ST01 / ST02 | Transaction Set Header | Indicates start; control number must match SE. |

| BIA | BIA01–BIA05 | Beginning Segment | Defines purpose (00=Original, 05=Replace, 25=Incremental). |

| CUR | CUR01 / CUR02 | Currency | Specifies transaction currency (USD, CAD, GBP). |

| DTM | DTM01–DTM04 | Date/Time Reference | Identifies Effective (007), Report Start (090), Report End (091). |

| REF | REF01–REF03 | Reference ID | Associates batch/lot references. |

| N1 | N101–N104 | Name | Identifies sender (FR), receiver (TO), shipper (SH), supplier (SU). |

| LIN | LIN01–LIN05 | Item Identification | Specifies product identifiers and sequence numbers. |

| QTY | QTY01–QTY02 | Quantity | Indicates available or on-hand inventory. |

| SE | SE01–SE02 | Transaction Trailer | Ends transaction and verifies count integrity. |

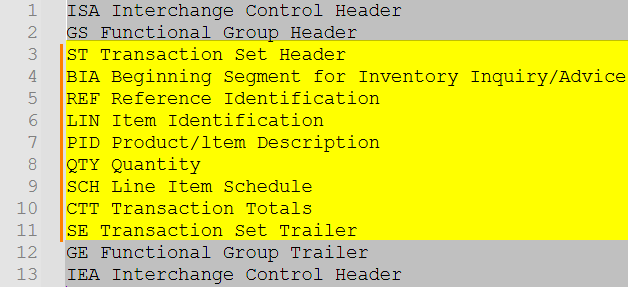

What are the Common Segments Included in the EDI 846 Inventory Inquiry/Advice?

| Segment | Mandatory/Optional | Usage Description |

|---|---|---|

| ST | Mandatory | Identifies the beginning of the transaction. |

| BIA | Mandatory | Establishes an inventory report type. |

| DTM | Optional | Defines effective reporting dates. |

| N1 | Optional | Used to identify warehouses, entities in control of inventory positions, and locations. |

| LIN | Mandatory | Lists unique product identifiers. |

| QTY | Mandatory | Reports on the inventory levels. |

| CTT | Optional | Identifies Hash Totals – providing a reconciliation mechanism. |

| SE | Mandatory | Identifies the End of the transaction. |

What Status Codes are used with the EDI 846 Inventory Inquiry/Advice?

The BIA segment serves as a starting point of the EDI 846, regardless of direction (Inquiry or Advice), setting the stage for an inquiry or for a detailed inventory response, details provided in subsequent segments (e.g., LIN, QTY, so-on).

- 00 – Original Transmission

- 05 – Replace Existing

- 25 – Incremental Update

What Reason Codes are used with the EDI 846 Inventory Inquiry/Advice?

While  Reason Codes are not defined in the public X12 004010 standard, reasons codes are however used for internal classification purposes and can be inferred through the use of other data sources in a generic sense.

Reason Codes are not defined in the public X12 004010 standard, reasons codes are however used for internal classification purposes and can be inferred through the use of other data sources in a generic sense.

- OSD – Over/Short/Damaged stock

- DTM01 = 007 Effective

- G5301 Maintenance Type Code = 022 Change in Status

- REF01 = QJ Return Material Authorization Number

- REF01 = RZ Returned Goods Authorization Number

- CC – Cycle Count variance

- DTM01 = 043 Publication

- G5301 Maintenance Type Code = 010 Periodic Report

- REF01 = AM Adjustment Memo

- EOM – End-of-Month adjustment

- G5301 Maintenance Type Code = 026 Correction, 001 Change

- REF01 = RS Returnable Container Serial Number

- DTM01 = 009 Process

- ADJ – Administrative or system correction.

- DTM01 = 405 Production

- G5301 Maintenance Type Code = 030 Audit or Compare

- REF01 = BP Adjustment Control Number

What Use Cases does the EDI 846 Inventory Inquiry/Advice support?

- Buyer

requesting current stock availability from supplier.

requesting current stock availability from supplier. - Supplier or warehouse reporting when inventory conditions change.

- Supplier or warehouse reporting inventory to retailers (End of Month Activities)

- Supplier or warehouse reporting when inventory conditions change as a result of cycle count.

- Multi-warehouse balancing across ERP systems.

- Internal stock reporting for manufacturing or distribution sites.

What are the Benefits of the EDI 846 Inventory Inquiry/Advice?

- Reduced manual reconciliation.

- Improved planning and forecasting accuracy.

- Enhanced order-to-cash cycle efficiency.

- Reduced carrying costs and overstock.

- Automated data synchronization between partners.

How efficient is the 846 Inventory Inquiry/Advice?

The EDI 846 Inventory Inquiry/Advice reduces manual reconciliation through automation. It streamlines updates, replacing manual spreadsheets with automated, near-real-time feeds. The 846 accelerates book inventory balancing, helps ensure ATP (Available-to-Promise) planning, fill rates, and financial accuracy (posting). Typical implementations report reductions in inventory visibility latency by upwards of 80%.

How compliant is the EDI 846 Inventory Inquiry/Advice?

The  EDI 846 Inventory Inquiry/Advice aligns with X12 v4010 standards, GS1 SSCC, EPC guidance, and common AS2 transport practices and protocols, The 846 supports global warehouse networks and industry audit controls and is used in PartnerLinQ-connected ecosystems.

EDI 846 Inventory Inquiry/Advice aligns with X12 v4010 standards, GS1 SSCC, EPC guidance, and common AS2 transport practices and protocols, The 846 supports global warehouse networks and industry audit controls and is used in PartnerLinQ-connected ecosystems.

- X12 v4010 structure

- Support for GS1 SSCC labeling

- EPC/RFID compliance when applicable

- Standard EDI control structure and acknowledgments

What is the Format of the EDI 846 Inventory Inquiry/Advice?

The EDI 846 uses the ANSI X12 Warehouse Inventory Adjustment Advice for digital stock alignment with physical inventories, shipment adjustments, and warehouse receipt adjustments.

How Accurate is the EDI 846 Inventory Inquiry/Advice?

Accuracy depends on synchronized master data, identifiers, location codes, and partner code lists; validation of ST/SE control numbers and mandatory content supports processing integrity.

- Synchronized item and location master data.

- Valid SSCC/lot/serial identifiers

- SSCC and serial validation when used.

- Time-aligned ERP and WMS posting cycles.

- Strong discrepancy handling processes

PartnerLinQ validates each inbound/outbound file through automated schema, quantity, and partner ID checks. GLN and QTY data are cross verified before posting.

What are the Limitations of the EDI 846 Inventory Inquiry/Advice?

Limitations of the EDI 846 Inventory Inquiry/Advice include automation and technical capabilities. The EDI 846 provides exceptional query and response capabilities which requires strong control (discipline) and automation of query response and of course master data maturity to ensure data alignment.

- Requires partner alignment on frequency and format.

- May omit untagged product conditions without proper REF codes.

- Dependent on ERP/WMS data timeliness.

Are Guidelines & Sample Files for the EDI 846 Inventory Inquiry/Advice available?

Yes. Sample EDI 846 Inventory Inquiry/Advice and implementation guides that support testing and partner onboarding are available through PartnerLinQ.

PartnerLinQ provides:

- EDI 846 implementation guide

- Validated sample payloads.

- Qualification and testing maps

- Standard error handling, exception handling guidance, and best-practice notes

What are the Basic Questions for EDI Integration with the EDI 846 Inventory Inquiry/Advice?

- Are there Samples and Specs available?

- What is the general direction of the transaction?

- Are they Inbound from or Outbound to another party?

- Are there more than one trading partner exchanging the EDI 846 Inventory Inquiry/Advice?

- Are there other interested parties?

- What transactions might these interested parties be a party to?

- What response to the transaction is expected or sent in response to the transaction?

- Is a response to the transaction a timed event? Are notifications involved/needed?

- Are there samples and specs of the response transaction available?

- What format and delimiter set will be used (~, *, >)?

- How are changes to the 846 Inventory Inquiry/Advice business message managed today?

- What triggers generation — scheduled or event-driven?

- Is there automation? (an internal systems trigger) Or are 846 Inventory Inquiry/Advice business message transactions triggered manually?

- What validation or acknowledgment timing is required?

- Are responses and changes automatically triggered? (an internal systems trigger) Or do transactions require human intervention?

What Business Level Workflow does the EDI 846 Inventory Inquiry/Advice support?

A typical PartnerLinQ workflow:

- Warehouse generates 846 advices.

- PartnerLinQ validates and routes it to ERP or customer system.

- Partner systems update dashboards or initiate replenishment.

- Exceptions trigger alerts or adjustment requests (947).

What are the Best Practices for using the EDI 846 Inventory Inquiry/Advice?

Best Practices for using the EDI 846 Inventory Inquiry/Advice include (1) When inventory conditions change as might be the case when the warehouse operator encounters over, short or damaged (OSD) product; a condition which may be the result of warehouse damage, receiving damage, or previously concealed damage of product or products that occurred during shipping, loading, or unloading of a product within a carton and/or within a shipment previously received. (2) When inventory conditions change as a result of cycle counting. Trading partner should consider requiring the Inventory Inquiry/Advice to be sent on completion of cycle counting on a daily, weekly, or monthly basis as might be prescribed by agreement between the warehouse and the depositor to ensure that both parties are accounting for changes in inventories in the same way. (3) Resulting from End of Month Activities – Partners often require an Inventory Inquiry/ Advice to be sent on a monthly basis as might be prescribed by End of Month Activity outlines by agreement between the warehouse operator and the depositor to ensure that both parties are accounting for changes in inventories in the same way

Practices for using the EDI 846 Inventory Inquiry/Advice include (1) When inventory conditions change as might be the case when the warehouse operator encounters over, short or damaged (OSD) product; a condition which may be the result of warehouse damage, receiving damage, or previously concealed damage of product or products that occurred during shipping, loading, or unloading of a product within a carton and/or within a shipment previously received. (2) When inventory conditions change as a result of cycle counting. Trading partner should consider requiring the Inventory Inquiry/Advice to be sent on completion of cycle counting on a daily, weekly, or monthly basis as might be prescribed by agreement between the warehouse and the depositor to ensure that both parties are accounting for changes in inventories in the same way. (3) Resulting from End of Month Activities – Partners often require an Inventory Inquiry/ Advice to be sent on a monthly basis as might be prescribed by End of Month Activity outlines by agreement between the warehouse operator and the depositor to ensure that both parties are accounting for changes in inventories in the same way

- Send daily inventory advices for omnichannel operations.

- Include DTM qualifiers 007 Effective / 090 Report Start / 091 Report End as timestamps to improve accuracy.

- Use GLN identifiers for all N1 locations.

- Automate generation of the EDI 846 Inventory Inquiry/Advice on cycle count completion.

- Automate generation of the EDI 846 Inventory Inquiry/Advice in response to a query.

- Replace, do not overwrite inventory transactions— use a ‘change by refresh’ process that includes a cancelation or BIA05 = Replace or BIA25 = Incremental to add to the previous statement additional inventory items.

What Transactions are associated with the EDI 846 Inventory Inquiry/Advice?

| Transaction | Purpose |

|---|---|

| 850 | Purchase Order – Initiates procurement demand. |

| 855 | Purchase Order Acknowledgment – Confirms PO receipt. |

| 856 | Advance Ship Notice – Communicates shipment details. |

| 860 | Purchase Order Change – Reflects order updates. |

| 947 | Inventory Adjustment Advice – Reconciles warehouse updates. |

Footnotes

- PartnerLinQ 846 v4010 Specification, June 2025.

- PartnerLinQ EDI Notes 20180917.

- PartnerLinQ Internal Implementation Guidelines.

- ANSI X12 v4010 Standard Reference.