What is the EDI 860 - Purchase Order Change Request?

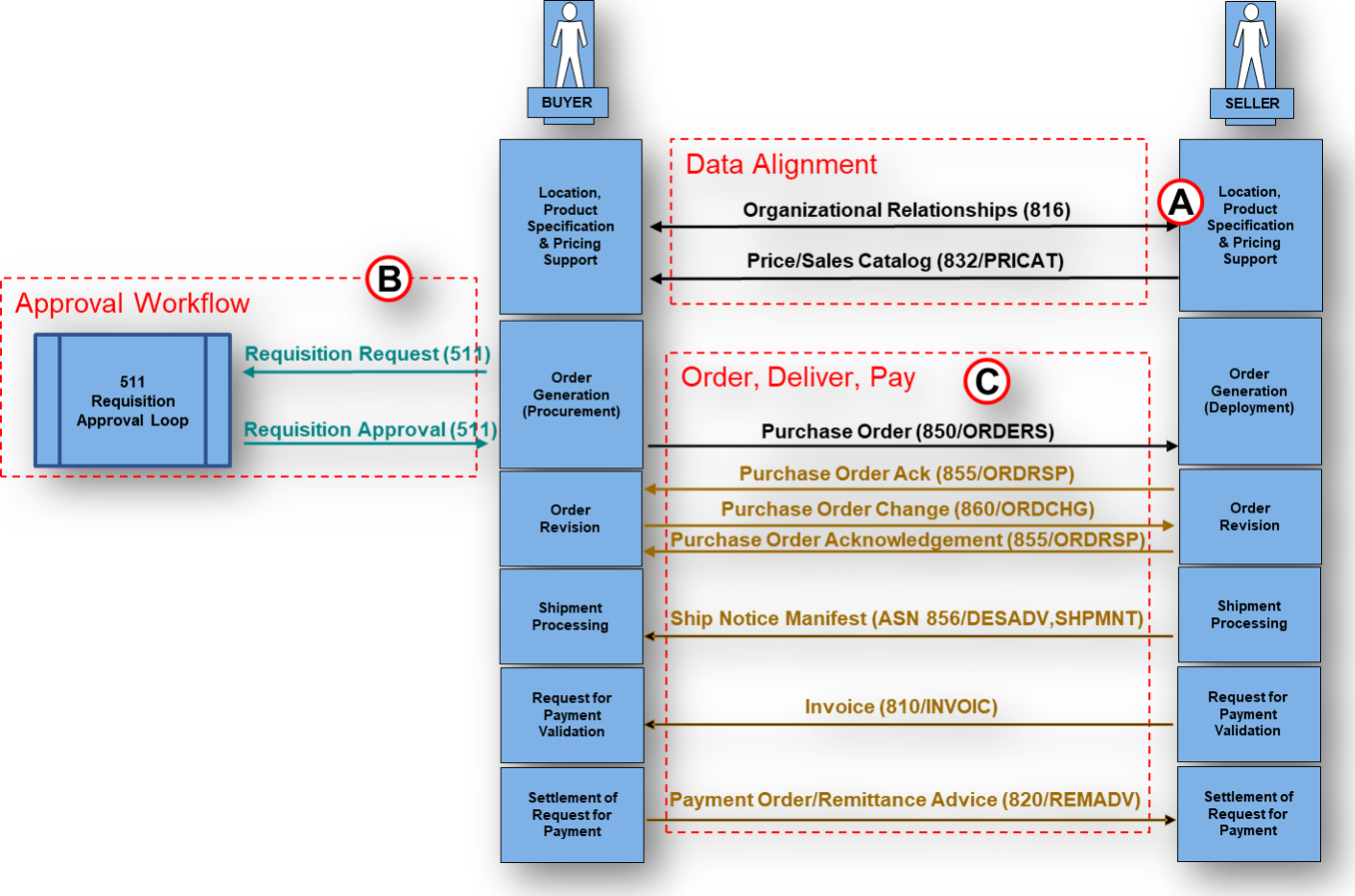

The EDI 860 Purchase Order Change Request is used by buyers to request modifications to a previously submitted EDI 850 Purchase Order. It communicates changes such as quantity, date, price, or item adjustments. The 860 ensures that both trading partners remain aligned when purchase orders need to be updated after initial transmission.

How does PartnerLinQ use the EDI 860?

PartnerLinQ uses the Purchase Order Change Request (860) as a method to communicate purchase order changes into procurement workflows, enabling automated handling of change requests within ERP and OMS systems. The EDI 860 is a key to validating modifications, updating downstream supply chain processes, and providing visibility across procurement and fulfillment cycles. The method of PO change represented by the EDI 860 Purchase Order Change Request reduces miscommunication, delays, and costly order errors.

While the Purchase Order (850) is used by PartnerLinQ to express purchase order information, advise the seller or broker of a request for the delivery of the product and other purposes, the information used in the Purchase Order Change Request (860) communicates changes, additions, or deletions to a previously transmitted Purchase Order (850). The information used by the 860 comes from the same sources and is used: (1) by a buyer to submit a change to a previously submitted purchase order to the seller or (2) by a buyer to communicate acceptance of a purchase order change initiated by the seller or by mutual agreement of the two parties.

What responses to the EDI 860 Purchase Order Change Request are expected or sent?

The 860 represents the buyer’s plan to make changes to an existing 850 when changes are required. It may trigger a seller’s confirmation through the 855 Purchase Order Acknowledgment or 865 Purchase Order Change Acknowledgment, in order to ensuring mutual agreement on the original order, updated order, shipping, dating, terms or conditions.

What does the EDI Purchase Order Change Request (860) support?

The Purchase Order Change Request (860) supports procurement by allowing modifications without canceling and reissuing entire purchase orders. The EDI 860 facilitates a structured, automated communication for managing order modifications between buyers and sellers assisting both sides manage purchasing activities dynamically and accurately. The Purchase Order Change Request (860) provides audit trails, supports compliance, and reduces inefficiencies in dynamic supply chains.

What are the Key Features of the EDI 860 Purchase Order Change Request?

- Communicates order modifications (item, quantity, price, date)

- Enables partial or complete changes

- Supports header level and line level changes

- Supports cancellation or rescheduling of items

- Integrates with ERP/OMS workflows

- Triggers seller acknowledgment through the 865

What is the Purpose of the EDI 860 Purchase Order Change Request?

The purpose of the 860 is to streamline buyer-driven order changes while preserving visibility and compliance across procurement and fulfillment. The EDI 860 serves as a critical instrument within the digital procurement lifecycle, enabling buyers to formally request modifications ensuring that procurement and supplier systems remain synchronized when purchase requirements evolve.

What Information is included in the EDI 860 Purchase Order Change Request?

The 860 includes:

- Original PO reference (BCH, REF)

- Change request identifiers (BCH01, POC02)

- Updated item and price details (POC, CTP)

- Scheduling and date changes (DTM)

- Reason codes for modifications (REF,SAC)

- Totals and summary information (CTT,SE)

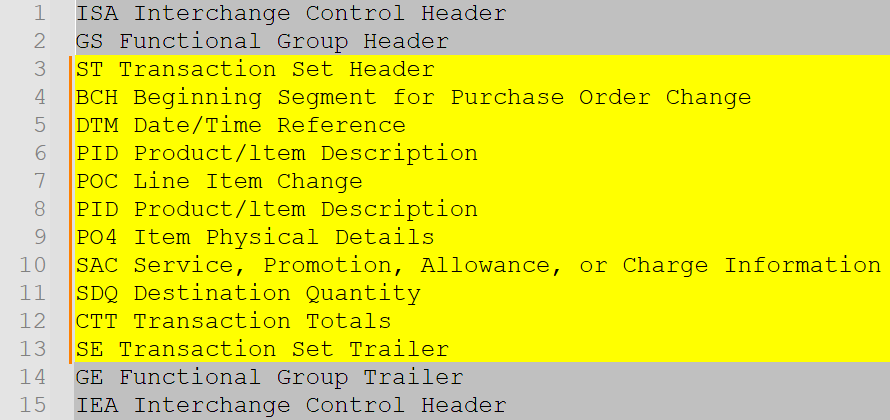

What are the Essential Components of the EDI 860 Purchase Order Change Request?

| Segment | Description |

|---|---|

| ST | Transaction Set Header |

| BCH | Beginning Segment for Purchase Order Change |

| CUR | Currency |

| REF | Reference Identification |

| PER | Administrative Communications Contact |

| FOB | F.O.B. Related Instructions |

| SAC | Service, Promotion, Allowance, or Charge Information |

| ITD | Terms of Sale/Deferred Terms of Sale |

| DTM | Date/Time Reference |

| N1-N4 | Name and Address segments |

| POC | Line Item Change Information |

| CTT | Transaction Totals |

| SE | Transaction Set Trailer |

What are the Common Segments included in the the EDI 860 Purchase Order Change Request?

| Segment | Description |

|---|---|

| BCH | Change request header |

| REF | Purchase order references |

| N1 loop | Buyer, Seller, Ship-to |

| POC | Item changes |

| DTM | Date/Time changes |

| SAC | Allowances/Charges |

What Status Codes are used with the EDI 860 Purchase Order Change Request?

Status codes in BCH01 may indicate

- 00 = Original

- 01 = Cancellation

- 04 = Change

…and qualifiers in the BCH02 identify the type of PO change (e.g., release, blanket).

What Reason Codes are used with the EDI 860 Purchase Order Change Request?

While  a ‘Business Need’ often serves as default rationale for PO change and is not required in the standard, rationale does itself serve a ‘Business Need’ and for that reason ‘Reason Codes’ may appear in REF or SAC segments to specify why a change is/was requested.

a ‘Business Need’ often serves as default rationale for PO change and is not required in the standard, rationale does itself serve a ‘Business Need’ and for that reason ‘Reason Codes’ may appear in REF or SAC segments to specify why a change is/was requested.

Examples include:

- Price adjustment

- Quantity change

- Delivery reschedule

- Item substitution

What Use Cases does the EDI 860 Purchase Order Change Request support?

The EDI 860 Purchase Order Change Request supports multiple procurement scenarios where agility and precision intersect, empowering organizations to maintain control over procurement while adapting to real-time operational supply, demand, or constraint.

| Scenario | Description |

|---|---|

| Schedule Revisions | Procurement teams adjust requested ship or delivery dates to align with new production timelines or distribution center capacity. |

| Item Substitutions | When a supplier discontinues or replaces a product, the buyer issues an EDI 860 to update the item code and description while retaining the purchase order reference. |

| Quantity Adjustments | A buyer modifies order quantities due to updated demand forecasts, production changes, or inventory optimization strategies. |

| Price or Terms Updates | Used to reflect updated items, quantity, price, terms, (re-negotiated) corrections, contract amendments, even rebates. |

| Partial Order Cancellations | Enables buyers to cancel specific line items or quantities within a larger purchase order while preserving valid order lines. |

| Ship-To or Distribution Changes | Updates to delivery points, regional warehouses, or third-party logistics providers to support changing supply chain networks. |

What are the Benefits of the EDI 860 Purchase Order Change Request?

The EDI 860 Purchase Order Change Request streamlines procurement by enabling automation and modifications to purchase order are accurate, visible, and synchronized, eliminating manual communication gaps between buyers and suppliers, minimizing order discrepancies, accelerating change-cycles, execution and impact on supply chains.

- Enhances collaboration through structured, automated feedback loops

- Renews insight into frequency, responsiveness, and impact of change

- Raises synchronization levels between buyer and supplier systems

- Improves agility in dynamic supply chains

- Enhances buyer/seller communication

- Avoids cancellation/reissue of orders

- Provides clear audit trail of changes

- Reduces operational friction

- Energizes exception resolution

| Benefit Area | Description |

|---|---|

| Procurement Accuracy | Maintains alignment between buyers and suppliers and their systems by automatically updating purchase orders. |

| Operational Efficiency | Replaces manual revisions, phone calls & emails with automated, structured communication. |

| Reduced Exceptions | Minimizes downstream exceptions between purchase orders, shipments, and invoices. |

| Improved Supplier Collaboration | Validates change requests that can be acknowledged. Improves synchronization, transparency, and responsiveness through automation, validation, and coordination (e.g., Change Management). |

| Compliance & Auditability | Provides a digital record of purchase order modifications supporting governance and accountability. |

| ERP Integration | Integrates with ERP procurement modules (SAP MM, Oracle Procurement Cloud, Microsoft Dynamics 365, etc.), ensuring synchronized transactional data. |

| Decision Intelligence Enablement | PO changes simultaneously feed into advanced toolsets (e.g., PartnerLinQ’s Smart Visibility and Decision Intelligence modules) allowing procurement leaders to monitor change, responsiveness, and impact in near real time. |

How Efficient is the EDI 860 Purchase Order Change Request?

The EDI 860 Purchase Order Change Request is the embodiment of efficiency, delivered as a procurement model replacing the ambiguity of manual change management with digital precision and in near real-time

- The EDI 860 delivers an orchestrated partner to partner exchange through structured digital collaboration.

- The EDI 860 enables purchase order adjustment quickly without restarting or interrupting the business cycle.

- The EDI 860 delivers modernization through automated partner to partner communication for managing order modification with automated feedback loops that eliminate errors.

Every adjustment—whether a revised quantity, delivery date, or pricing term—flows automatically from the buyer’s procurement system to the supplier’s order management environment, validated, acknowledged, and archived, all without delay. The EDI 860 Purchase Order Change Request doesn’t merely support efficiency—it defines it, embodying the very principle of streamlined, data-driven excellence.

How Compliant is the EDI 860 Purchase Order Change Request?

The EDI 860 supports trading partner compliance programs and reduces inefficiencies in dynamically charged supply chains. It provides a clear audit trail of changes, preserves visibility across procurement and fulfillment cycles, reducing miscommunication ensuring that both trading partners remain aligned when purchase orders need to be updated after initial transmission.

What is the Format of the EDI 860 Purchase Order Change Request?

The EDI 860 Purchase Order Change Request follows ASC X12 v4010 standards for Purchase Order Change Request with PartnerLinQ delimiters meeting GS1, UCS, VICS, and trading partner requirements.

How accurate is the EDI 860 Purchase Order Change Request?

The EDI 860 Purchase Order Change Request, like its 850-purchase order predecessor, standardizes data exchange in the change management loop between buyers and suppliers for a consistent, repeatable order exchange, replacing the ambiguity of manual change management with digital precision ensuring both parties can confirm order modifications prior to fulfillment.

What are the Limitations of the EDI 860 Purchase Order Change Request?

The EDI 860 Purchase Order Change Request requires a timely understanding of the procurement process which may include acknowledging sellers and a well thought out rationalized understanding of partner procurement, sales, distribution, and fulfilment models. When paired properly with acknowledgement and understanding. The EDI 860 can be a strategic advantage in misalignment avoidance.

Are Guidelines and Sample Files for the EDI 860 Purchase Order Change Request available?

Yes. PartnerLinQ provides sample EDI 860 Purchase Order Change Request Transaction and implementation guides through its Support and Guideline Management Team.

Sample EDI 860 implementation guides illustrate both inbound and outbound flows, segment layouts, and valid data examples and support testing and partner onboarding. Customized specification documents for use in on boarding and technical development are available upon request.

PartnerLinQ provides:

- EDI 860 Purchase Order Change Request transaction implementation guide

- Sample payloads

- Qualification and testing maps

- Error handling and best-practice notes

What are the Basic Questions for Integration of the EDI 860 Purchase Order Change Request?

- Are there Samples and Specs available?

- Which X12 version (e.g., 4010, 5010) and implementation guide (e.g., VICS, AIAG) are we using for the 860?

- Are the EDIFACT ORDCHG transactions also involved? ( to align on standards and avoid version mismatches.)

- Are there specification files for various trading partners and for all types of Order Changes?

- What is the general direction of the transaction?

- Are they Inbound or Outbound relative to direction?

- Are there other parties interested in this transaction?

- What transactions might these parties be interested in?

- Are changes to the 860 PO change business message expected?

- What trading partner-specific variations (e.g., custom qualifiers in REF or date formats in DTM) need to be accommodated? (Accounts for bilateral agreements beyond standard X12.)

- How do we define success with the EDI 860? (Outline validation and go-live criteria for the integration.)

- How will sellers confirm receipt of the 860?

- What response/acknowledgement is expected or sent in response to the transaction?

- Is a response/acknowledgement of the transaction a timed event?

- Are response/acknowledgement notifications involved or are reminders needed?

- How are changes to the 860 PO change business message managed today?

- What is the primary business trigger for sending an 860? (E.g., manual PO changes via ERP, automated inventory adjustments, or supplier notifications to identify change initiation points.)

- The original Purchase Order number is required in the BEG03 to provide traceability back to the original order. How is the original Purchase Order identified, and how is a change detected?

- What business rules apply?

- At which status or process in the order-to-cash flow should modifications no longer be allowed? (usually, it is when the order is allocated or released to the warehouse)

- What if there is no order against the received EDI 860?

- What if the order has already shipped?

- What are the cancellation scenarios?

- How should errors or acknowledgments be handled (e.g., via 997 FA or 865 PO Acknowledgment responses)? What are the retry and escalation policies? (Defines error resolution and confirmation workflows.)

- Is there automation involved? (an internal systems trigger) Or are 860 PO change business message transactions triggered manually?

- Are responses automatically triggered, or do transactions require human intervention?

- What change types (cancel, modify, reschedule) are supported?

- What types of Purchase Order changes are most common?

- Are partial line changes allowed?

- What Purchase Order detections need to be in place now that a Purchase Order change has been received?

- For line-level changes, are line assignments made or available (POC01)?

- For line-level changes, what types of modifications are most common? (e.g., quantity via POC02='PQ', cancellations via 'DI', or price updates)?

- What product/service ID qualifiers are used in the trade relationship? Are they consistent? (e.g., BP - Buyer's Part Number in POC08/09)

- Is there a cross-reference table available? Do you need one to support PO Change? (Prevents ID mismatches in item identification.)

- How should ERP handle rejected 860 requests?

- Are there any optional segments like CTB (Restrictions/Conditions) or PO4 (Item Physical Details) that must be supported, and what business rules apply? (Identifies non-standard requirements for conditions or dimensions.)

- Do you require scheduling details for changed lines (e.g., using SCH segments for delivery dates)? If so, how are ship-to locations handled? (Clarifies if advanced logistics integration is needed.)

- How will testing be conducted (e.g., sample 860 files, volume simulations), and what KPIs (e.g., processing time, accuracy rate)

What is the Business Level Workflow for the EDI 860 Purchase Order Change Request?

- Buyer issues original 850.

- Buyer identifies need for changes.

- Buyer sends 860 Purchase Order Change Request.

- Seller reviews and responds/acknowledges.

- Order proceeds under revised terms.

- Subsequent 856 ASN and 810 Invoice complete the cycle.

What are the Best Practices for using the EDI 860 Purchase Order Change Request?

The EDI 860 Purchase Order Change Request exemplifies how efficiency and governance can coexist. When well supported by automation, real-time validation, and Decision Intelligence dashboards, every change request becomes a moment of operational clarity rather than disruption. The EDI 860 has the ability to transform a ‘business need’ from reactive adjustment to strategic advantage —It is a precise, data-driven reflection of agility, accountability, and supplier collaboration when best practices are employed.

| Process Stage | Outbound (Buyer-Initiated) | Inbound (Supplier-Received) |

|---|---|---|

| Governance & Control | Treat the 860 as a controlled document by validating purchase order changes through internal workflows before generating the EDI 860. | Confirm receipt of incoming messages, automate cross-checks for trading partner IDs, purchase order references, fulfillment status, and inventories. |

| Functional Acknowledgment | Require immediate 997/999 acknowledgments to confirm successful transmission and syntax validation. | Send 997/999 acknowledgments promptly to confirm receipt and structural validity; automate this step to maintain SLA compliance. |

| Change Acknowledgment | Consider a formal supplier response via EDI 865 PO Change Acknowledgment, indicating acceptance, rejection, or conditional approval of a change request. | Consider transmitting the EDI 865 for every 860 received to make acceptance status known or to provide alternate proposals. |

| Exception Management | Configure automated exception handling to highlight unrecognized changes and route them to buyers. | Configure automatic exception workflows to highlight conflicting or unrecognized changes and route them to account managers or customer service teams. |

| Automation and Synchronization | Ensure that ERP and EDI environments are synchronized such that changes in the ERP automatically trigger the EDI 860. | Align inbound changes with ERP or OMS (Order Management System). Automate status checks, order updates, fulfillment schedules, and internal notifications. |

| Version Control & Auditing | Maintain historical visibility of all 850/860 iterations by connecting 860 change(s) with the corresponding 850. | Archive all inbound EDI 860 and outbound EDI 865 PO Change Acknowledgment in a structured data repository to support audit, compliance, and supplier KPI reporting. |

| Monitor Timeliness (SLAs) | Ensure alignment – establish or define confirmation and acknowledgement timelines, measure supplier responsiveness, and track adherence. | Track turnaround times for each order, change, and acknowledgment and use metrics to improve performance, service levels, and benchmark results. |

| Data Standardization | Standardize use cases, reason codes, change types, timing, and reference qualifiers to ensure partner compliance. Minimize change reason codes. | Mirror buyer data standards and maintain translation maps for consistent inbound interpretation. |

| Decision Intelligence | Leverage analytics with your newly discovered SLAs to identify key drivers of change, volatility drivers - lead time and demand, price and quantity variances for supply chain success. | Leverage order, change, acknowledgment, and fulfillment data into analytics to detect bottlenecks or forecast disruptions caused by late or frequent change requests. |

| Continuous Collaboration | Conduct periodic reviews with peers and competitors to refine your EDI 860 workflows and ensure alignment with suppliers. | Conduct periodic reviews or participate in joint improvement sessions with trading partners to refine EDI 860 workflows, review change cycle efficiency, exception frequency, and automation maturity. |

What Transactions are associated with the EDI 860 Purchase Order Change Request?

| Transaction | Description | Relationship to EDI 860 |

|---|---|---|

| EDI 850 – Purchase Order | Original order initiating procurement activity. | The 860 references and modifies the 850 by line item or segment. |

| EDI 855 – Purchase Order Acknowledgment | Supplier confirmation of order receipt or acceptance. | The 860 may follow an 855 if buyer changes occur post-acknowledgment. |

| EDI 865 – Purchase Order Change Acknowledgment/Request – Seller Initiated | Supplier response to an EDI 860, confirming acceptance or rejection of changes. | Completes the change management loop between buyer and supplier. |

| EDI 856 – Advance Ship Notice (ASN) | Communicates shipment details. | ASN data must align with the latest version of the purchase order as modified by the 860. |

| EDI 810 – Invoice | Billing document from supplier to buyer. | Ensures billing reflects accurate item quantities, pricing, and terms post-change. |

| EDI 997 / 999 – Functional / Implementation Acknowledgment | Technical acknowledgments confirming receipt and syntactical validity. | Confirms successful electronic transmission of the 860 to the supplier’s EDI system. |

Explore Our Integration Solutions

PartnerLinQ Integration Solutions

Connect Everything. Integrate Intelligently.

Future-Proof Your Business with Composable, AI Powered Connectivity.