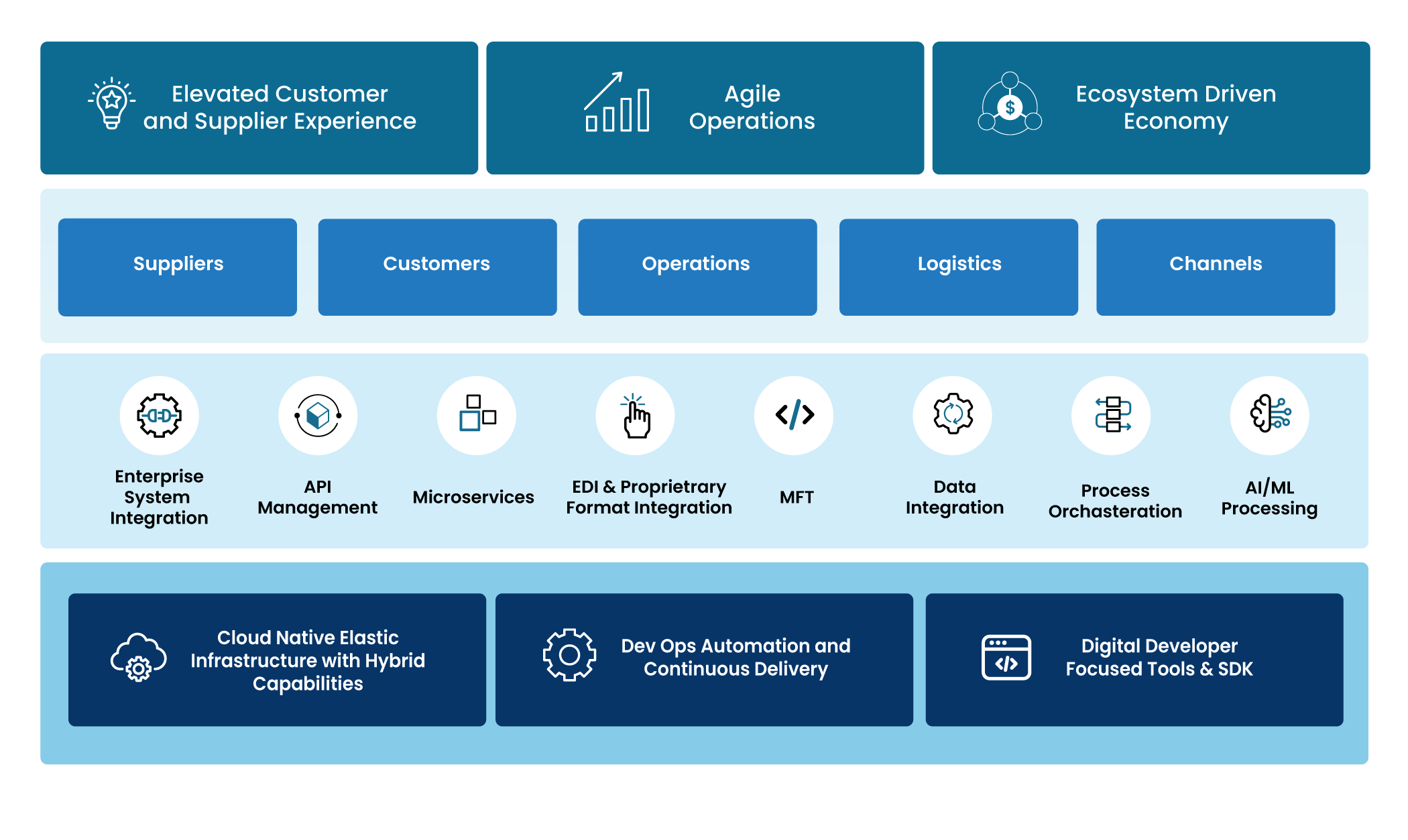

Every supply chain, regardless of its size, is an integral part of a broader value chain consisting of customers, suppliers, service providers, each with its unique operational model and tiered ecosystem. The imperative for supply chain businesses, both big and small, is to attain digital proficiency and operate with agility and precision amidst the rapidly changing landscape shaped by geopolitical and economic forces.

Key required digital capabilities include connectivity with EDI, API’s, data driven analytics as well orchestrating processes across the entire ecosystem. The ultimately goal is to achieve a unified view of enterprise-wide operations and optimize execution where digital meets with the physical supply chain to ensure timely decision-making and action.

As technology evolves and data assumes a central role in decision-making, the continuous evolution and optimization of the digital landscape are paramount. Organizations that stay at the forefront of digital innovation are better positioned to adapt, thrive, and succeed in today’s competitive environment.

Journey from EDI only to APIs

Leveraging traditional methods of supply chain connectivity such as Electronic Data Interchange (EDI), Application Programming Interfaces (APIs), and File Transfer technologies in isolation is no longer sufficient to meet the demands of modern commerce. The increasing complexity of global supply chains and the evolution of technology require a broader range of hybrid capabilities seamlessly fused together to truly digitalize and transform how businesses collaborate and operate.

While EDI remains a vital component of supply chain connectivity, gone are the days when EDI was the primary means of exchanging business documents between trading partners. The traditional EDI of our predecessors often lacked the flexibility and real-time capabilities needed to keep pace with today’s dynamic business environment. APIs have emerged as a more agile alternative to traditional EDI messaging, enabling real-time data exchange and integration between disparate systems. Yet, relying solely on API technologies, as we have seen in recent years, may not be enough and practical to address the diverse integration and vast communication needs of a truly modern supply chain.

Elevating Integration to Dynamic Digital Connectivity

There is an ever-increasing need for interconnectedness in the modern world, businesses no longer operate in isolation; rather they are part of a complex ecosystem involving suppliers, partners, intermediaries, carriers, customers, and more. Modern supply chain connectivity therefore must remain flexible to extend beyond the boundaries of individual relationships. Businesses must be able to seamlessly connect with multiple layers of internal and external partners to streamline processes, optimize workflows, and drive value across the supply chain ecosystem.

Holistic Digital Connectivity (beyond silo’s Integrations)

Enterprises today require a holistic more modern approach to supply chain connectivity—one that combines the strengths of EDI, APIs, traditional and emerging technologies to create a seamless and interconnected network approach to systems, partners, and processes. This approach, often referred to as hybrid integration, leverages a combination of cloud-based and middleware technologies, plus advanced integration, and data capabilities to bridge the gap between legacy and truly modern applications.

Degree of Interoperability

One of the key pillars of modern supply chain connectivity is interoperability. Businesses must be able to exchange data seamlessly with partners, suppliers, and customers regardless of systems, protocols, or preferences. This requires flexible integration solutions that transform various formats, understand multiple standards or protocols, and navigate partner preference to deliver smooth communications that traverse the ecosystem. What is more, these flexible integration solutions need to be easy to configure, simple to understand, and readily available when called to action.

Real Time Visibility

Another essential aspect of modern supply chain connectivity is real-time visibility. Today’s business users live in a digital era and demand instant access to accurate, up-to-date information about inventories, orders, shipments, and statuses. Achieving this level of visibility, sensitivity, and sophistication requires advanced data analytics capabilities, AI-driven insights, and IoT-enabled sensors that can capture and analyze data in real-time, providing actionable intelligence to decision-makers on a timely basis. Here too, visibility tools need to be easy to configure, simple to understand, and readily available when called into action.

The Role of Composability in Dynamic Digital Business Integration

Composability plays a crucial role in enabling businesses to deploy new business capabilities at a pace necessary for success through the reuse of integration/connectivity applications and options by leveraging industry specific modular and reusable components. Organizations can rapidly assemble and deploy integration solutions tailored to specific needs quickly, reducing time-to-market and accelerating innovation only when the right set of tools is available.

Moreover, the ability of IT analysts to bring solutions together with minimal effort and without hard coding becomes essential for achieving truly dynamic digital configurations. Modern configuration tools empower IT teams to orchestrate complex integration workflows, configure business rules, and customize data mappings without the need for extensive coding or scripting. This enables organizations to adapt quickly to changing business requirements and scale their integration capabilities as needed, driving increased agility and efficiency expected in the digital era.

In conclusion, the digital transformation of a supply chain requires a holistic approach to connectivity and delivers value—value that goes beyond traditional EDI and APIs activities and can accommodate multiple systems, various formats, standards, protocols, and preferences to integration to do so. Modern supply chain connectivity means embracing a hybrid integration strategy, fostering interoperability and real-time visibility, leveraging composability and digital configuration tools, then and only then can businesses create a truly interconnected and agile supply chain that enables collaboration, drives innovation, and delivers superior customer experiences in today’s hyper-connected world.

Jawad Khan, CEO & Founder, PartnerLinQ Inc.

Jawad Khan is the founder and CEO of PartnerLinQ. As the innovative force behind PartnerLinQ, Jawad guides the company in reshaping digital connectivity and collaborative intelligence within the extensive supply chain sector. His leadership philosophy is deeply rooted in ensuring that supply chains are not merely reactive but strategically positioned to respond to perpetual shifts in business demands swiftly and efficiently.