Delivering speed and agility

EDI logistics transforms supply chain operations by delivery speed and agility to the marketplace. Today’s markets, whether grocery & food service, building material/DIY market, fashion & apparel, general merchandise, home fashions, logistics, or transportation are dependent on information. The current year is no exception, coming into focus after Q1 and from all appearances it looks like EDI logistics is likely to have a bigger impact this year than in previous years, particularly with activity regarding tariffs.

Making supply chain operations more interesting this year, freight rates also reached new lows this (spring) season as ocean carriers looking to finalize their annual service contracts with shippers are making concessions in order to keep fleets full. Freight rate negotiation is an annual event that is taking place this year when more ships are expected to hit the water. More ships means more capacity, more capacity means increased (downward) pressure on price. Year-over-year lower container volume, adding to the downward pressure, is expected in some western US ports driven by shipping volumes pulled forward as a result of threats of new tariffs. Ocean carriers and shippers are reacting to the downward pressure and seem to withdrawing capacity, by planning to increase cancellations, fewer crossings means less capacity, less capacity means an increased pressure on price. Where is this headed? What is next for a supply chain operation engaged in international traffic?

The ‘churn’ in pricing markets can be tied back directly to the close monitoring of global events by just about everyone. Maybe, take a break today at or near the watercooler and observe everyday conversations discussing global trade. Tariffs, ships, even canal eco-systems, all playing a part in increased volatility and wider repercussions. Highways, bridges, drivers, trucks, containers, shortages, and outright outages translates into increased friction for land based transportation, land based transport, being the transport mechanism which inevitably follows a berthing.

The takeaway for supply chain operations managers from the most recent gyrations is clear, “stick to the plan.” There is probably no need to cancel orders or stock up on canned goods, everything is going to be fine and never bet against the US economy. The U.S. economy represents 25–27% of the global GDP so in terms of your 401k, variations in stock prices have all been pretty much accounted for and take it from me, none of us are retiring tomorrow.

What we know from history, is that ‘market corrections,’ small or large, are always followed by growth. Bears will be bears, bulls will be bulls, and supply chain managers should continue with business plans, as envisioned, as planned, and as designed. Managers should resist the tendency to allow periodic uncertainty to drive change. Change to agendas, changed planned out long before this most recent hype cycle and rely instead on the growth projections that were built into the plan. Growth after all, is inevitable and it shows in the US economy and never bet against the US economy.

Logistics transforms supply chains, and EDI logistics transforms supply chain operations by delivering speed and agility to those business plans, to the orchestration of B2B transactions, to the complex dance that connects buyers and sellers, products and placement, consumers, and commodities to markets and growth. Planning makes for good decisions, and execution makes for good management, good managers, and good stewards. Plan your work and work your plan.

Integration

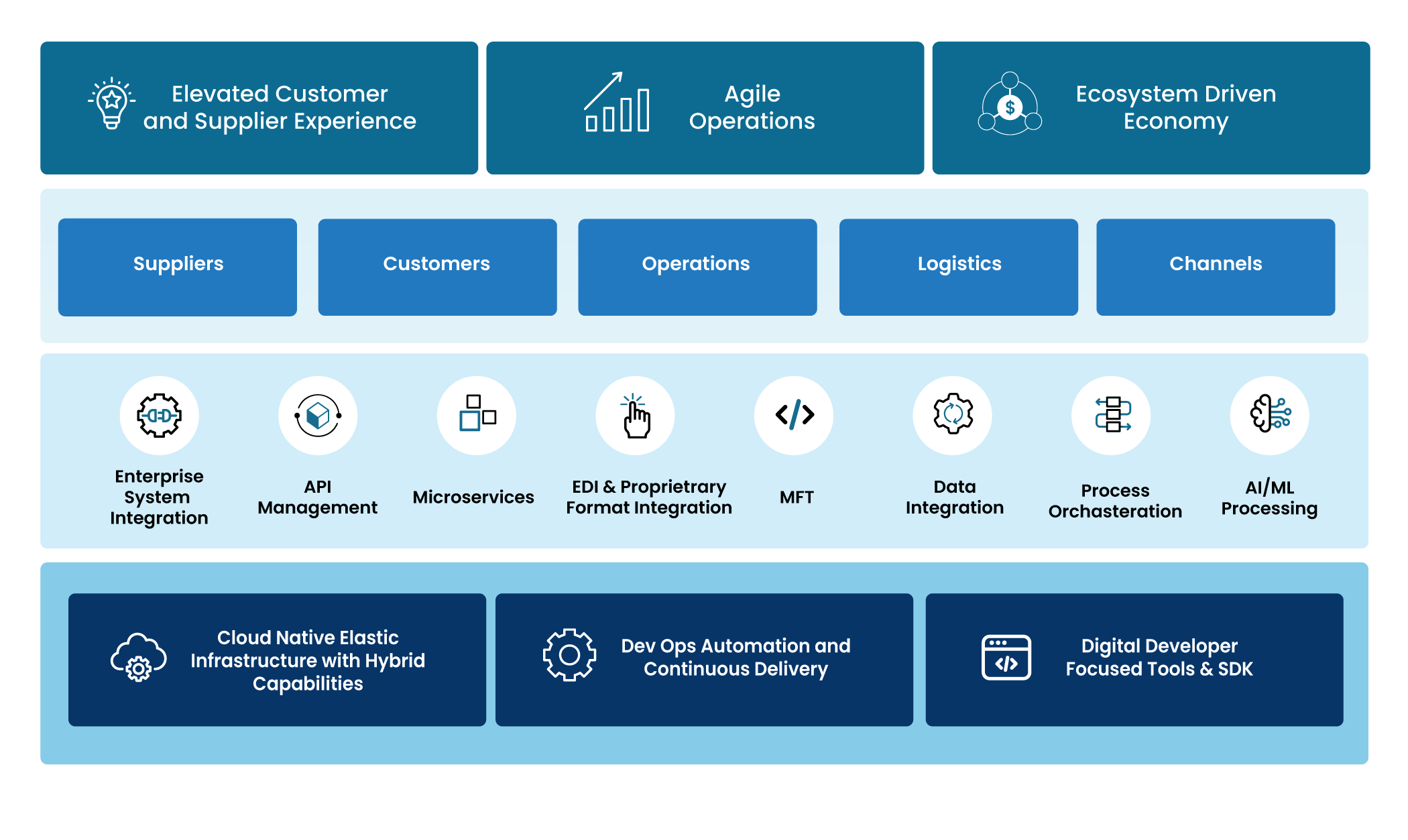

EDI logistics transforms supply chain operations by delivering integration speed and agility to disparate systems, important clients, and new partner relationships. EDI rejuvenates logistics in predictable ways by managing the previously unseen and unpredictable. Transactions and workloads today move through EDI through advanced cloud computing models designed to accommodate today’s business challenges, data, and data loads.

EDI logistics combined with digital connectivity solutions can transform data exchanges adding scalability and automation that empowers supply chain operations and streamlines workflows. Such levels of connectivity and interoperability, accommodated by prebuilt integrations and backed by on demand computing resources increase and enhance visibility. Leveraging data models from canonical to semantic, securely stored on cloud based resources, makes a difference, and delivers speed and agility.

Order to Cash

EDI logistics transforms supply chain operations by delivering speed and agility to the order to cash process by ensuring the buyer is advised of the delivery of the product. Order to cash EDI transactions contain data structures that allow buyer and sellers to exchange pertinent information related to logistics such as item references, carton, packing, or pallet configuration, and highly valued data in the logistics marketplace today.

EDI logistics increases the effectiveness of broadly defined activities, impacting staffing level in warehouses and transportation facilities. The benefits for logistics parties range from handling and error reduction to on-time shipments and faster invoice processing and since consumers receive the desired goods on time when EDI technologies are engaged in logistics and Supply chain operations , Days Sales Outstanding (DSO) is often reduced, and cash flows improved.

As many as 60% of US companies use EDI and they use EDI to communicate with their supply chains to do things such as place orders, track shipments and process invoices and the EDI community continues to grow. |

Scheduling and Tendering

EDI logistics transforms supply chain operations by delivering speed and agility to load tenders thereby enhancing operations even when reductions in capacity may mean cancelling shipments, putting deliveries on hold, or waiting for the next trans-oceanic voyage. Tender messages serve as a formal offer from a shipper to a carrier, the request is the transportation of a load of goods from one point to another, thus the term ‘load tender’ and the phrase to ‘tender’ the shipment.

Tender messages contain the information necessary to complete a point to point shipment, navigate a shipment with multiple destinations or ‘stops,’ even cancel a shipment. Tender messages include information such as the shipping origin, the destination or multiple destinations, and other information critical to the business process. Load tenders even serve as a legal bill of lading between the shipper and a carrier. Tender messages perform virtually the same function as an order in that a formal offer from a shipper to a carrier is made and an acceptance message follows, completing the ‘order’ process between the shipper and a carrier.

The load tender business message serves as the ‘shipment order’ and once the shipment has been made, completed, or cancelled, there is an end of life process, in most cases an invoice. Between the ‘shipment order’ and the ‘invoice’ is where ‘shipment status’ messages are exchanged between the shipper and the carrier. EDI logistics transforms supply chain operations by delivering speed, agility, and visibility, enhancing the business operation.

Tender Responses

EDI logistics transforms supply chain operations by delivery speed and agility to the tender response process. Shippers and carriers depend on load tenders and responses to complete supply chain planning activities and under the right condition a Response to a Load Tender indicates whether or not a delivery will be completed within the specified time frame.

Straight forward and timely by necessity, a response to a load tender indicates to the shipper that the carrier will accept, conditionally accept, or decline a load tender. An accepted load means that the carrier will manage the freight. A rejected load means that the carrier has declined the load. Responses are a timed event response must be received by the "Must Respond Date" and "Must Respond Time" information indicated inside of the motor carrier load tender. If a response to a load tender is not received by the "Must Respond Date" and "Must Respond Time" it is typically reassigned by the shipper or consignee and tendered to another carrier.

EDI logistics transforms Supply chain operations by delivery speed and agility to the tender response process. Exchanging response messages completes a process which allows for more complete supply chain planning. Speed and agility in the tender response process is enhanced through the use response messages, through the use of business rules and through advanced tools such as alerting when events contrary to the needs of the business are detected.

Where is my stuff?

EDI logistics transforms supply chain operations by delivery speed and agility to shippers, consignees, and entities responsible for the transportation of the shipment.

Historically shipment status messages were observed or processed only after the delivery of a shipment. Today, shipment status messages can be sent, received, and processed in near real time. Today, shipment status messages can be used to understand pickup, in-transit, and delivery status of shipments. Today, shipment status messages can be used to evaluate carrier performance in near real time for shippers and consignees leveraging shipment status and time to determine if transit times or schedules were met. Today, shipment status messages can be used for automated systemic consideration for estimated delivery dates.

DSO - Days Sales Outstanding

EDI logistics transforms supply chain operations by delivery speed and agility to cash flows. Days Sales Outstanding (DSO) measures the average number of days it takes a company to collect from a revenue source (buyer) after a sale has been made, the sale being consummated ONLY after the shipment has been made.

Accounting departments frequently measure and share their DSO with financial and accounting executives. DSO is an indicator of efficiency of the sellers’ accounts receivable process. When DSO is viewed in the context of 3 way match, DSO becomes an indicator of supply chain and logistics efficiency, similar to invoice processing or deductions management.

The shipment is made when responsibility for the shipment has been handed to another party in ‘tender and acceptance’ a messaging combination that signals a point in shipment processing that can also trigger a DSO calculation, thus ‘tender and acceptance’ is an indicator of logistics and supply chain efficiency.

In a 3 way match system, the invoice is processed (paid) when the shipment is received and in most financial and accounting ‘IF and ONLY IF’ the shipment has been received. 3-way match processing at a high level ensures that an invoice is accurate and should be paid. A process that involves verification, a process that ensures the alignment of three key documents before a payment is processed, a method that work exceedingly well to prevent errors, fraud, and overpayment.

The order has been placed, the shipment has been received, and the invoice matches the goods receipt. |

EDI logistics transforms supply chains by incorporating financial transactions into supply chain operations. Tenders, invoices, credit/debit adjustments, remittance and application advice transactions work together to complete the payment process in financial systems, completing the 3 way match process, signaling the end of the DSO calculation.

Conclusion

EDI logistics is a transformative framework that redefines speed, agility, and resilience of modern supply chain operations by integrating disparate systems, streamlining order-to-cash processes, and enhancing tendering, tracking, and financial workflows.

EDI logistics transforms supply chain operations by delivering speed and agility through enhanced visibility into the performance of logistics and supply chain actors.

EDI empowers businesses everyday by turning complexity into opportunity.

Want to take the conversation further? Request a demo with PartnerLinQ today and see how EDI logistics can transform your supply chain operations.

PartnerlinQ

PartnerlinQ